WELDING AND METAL SHEET WORKING.

Welding and Metal Sheet Working

We are specialists in

the manufacture of welded components and equipment with high quality requirements

We build your dreams

Machining parts

At ACEBRON GROUP we have prepared ourselves technically, throughout the manufacturing process, project management and quality control, to offer the best manufacturing solutions to our customers.

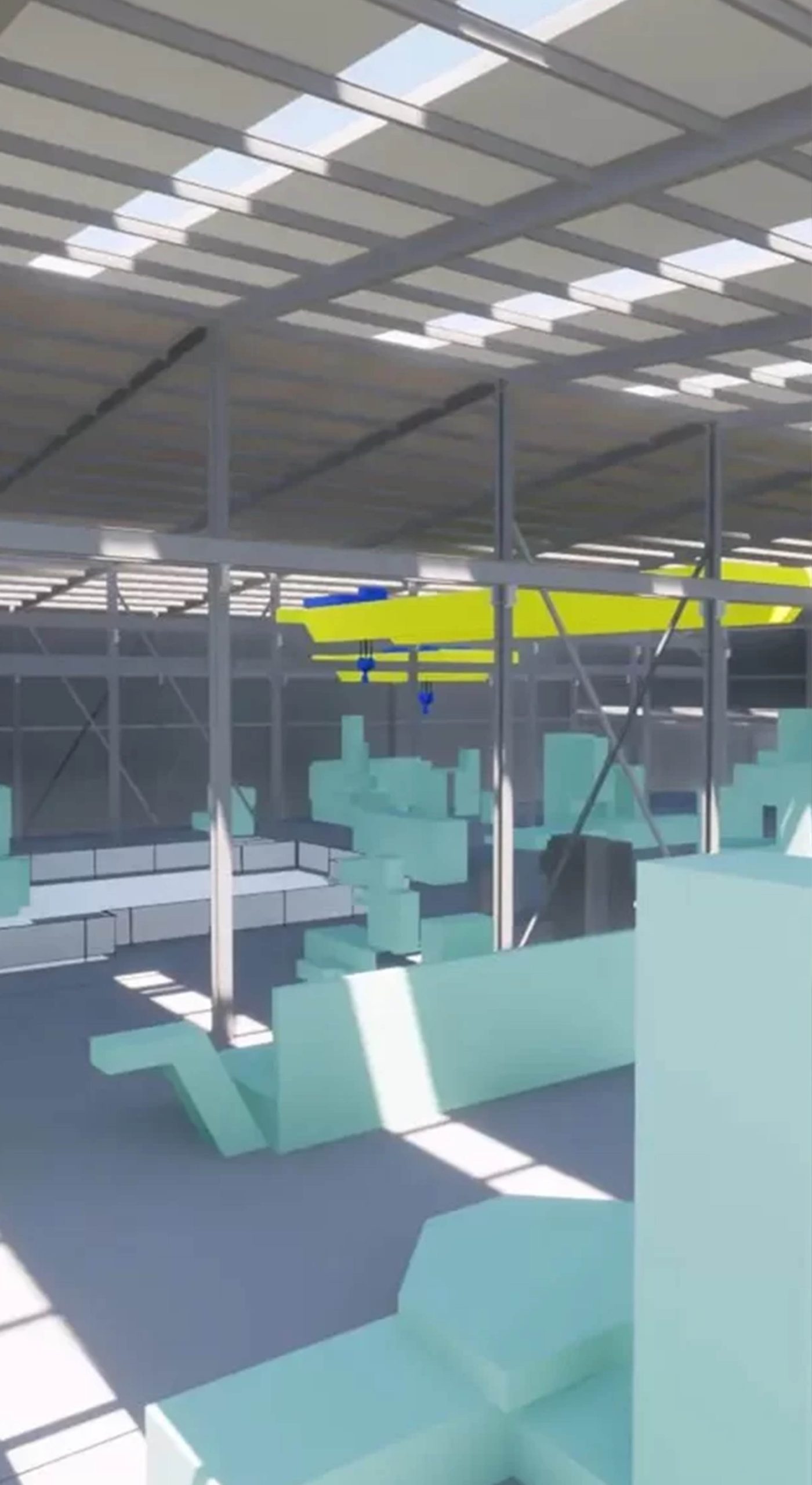

Our facilities of more than 6.400m2 and 12 metres high, allow us to take on projects of great importance and dimensions.

The welding process most widely used in ACEBRON GROUP is MIG / MAG. Welding with a large number of new generation machines, most of which have the possibility of using Pulsed Arc. Likewise, we have machinery for the SAW submerged arc processes, SMAW and TIG electrode processes. With these procedures we can guarantee the correct realisation in angle welds, T-joints and butt joints.

We offer a comprehensive manufacturing service and technical advice, including blank assemblies and quality assembly and quality testing to guarantee the quality of our work:

Services.

+ Manufacture of mechanical assemblies+ Manufacture of equipment+ Metal structures+ Refurbishment and repairs+ Special welding overlay+ Assemblies, pre-assemblies and blank assemblies+ Quality tests and trials (NDT, hardness tests, load tests, pressure tests…) |

+ Reverse engineering+ Detailed engineering and design+ Project management+ Technical advice |

WELDING AND METAL SHEET WORKING.

Using the latest materials

Innovation

Materials

The materials we usually work with range from Group 1 to Group 11 carbon steels, to Group 8 or other stainless steels. In recent years they have acquired special importance in our welding work, the Duplex Stainless Group 10 or carbon steels with good resilient capacities used in different projects carried out for offshore.

WELDING AND METAL SHEET WORKING.

Quality and certifications

Quality

We adapt ourselves to our customer requirements and specifications.

We have more than 40 qualified welding procedures under UNE 15614, AWS D1.1, DNV-C401, ASME IX.

Our manufacturing processes are certified according to EN 1090-1: 2009 / A1: 2011 and UNE EN ISO 3834-2: 2006, and we have a highly qualified engineering and product quality department:

- International Welding Engineer (IWE).

- Welded construction inspectors.

- Non Destructive Testing Technicians (UT, VT, PT, MP).

We carry out the most demanding quality controls to ensure maximum control, quality and safety of our products and services:

- Manual dimensional controls, with topographic equipment and laser tracker

- NDT

- Load tests

- Pressure tests

Our machinery capacities

Dimensions Welding and Metal Sheet Working Workshop | ||||

|---|---|---|---|---|

Entrance door dimensions | Workshop dimensions | Hook hight | Workshop height | |

| 6.000 x 8.500 mm | 40 x 160 (6.400 m2) | 9,75m | 12m | |

Sheet metal working capacities | ||||

|---|---|---|---|---|

Bending machine | Plate press | Shears | ||

Width | 2.500 mm | 3.000 mm | 2.500 mm | |

Thickness | 25 mm | 10 mm | 10 mm | |

Flame cutting | |

Dimensions | 12.000 * 3.000 mm |

Thickness | 2.200 mm |

Lifting means | 1×5 Tn. 1×10 Tn. 7×25 Tn. 1×32 Tn. 1×40 Tn. | 2×10 Tn. 1×16 Tn. 3×25 Tn. | 5×10 Tn. 1×16 Tn. 1×25 Tn. |

Max. Capacity Lifting | Machining | Metal Sheet Working | Surface Treatment |

50 Tn. | 50 Tn. | 26 Tn. | |

Workshop dimensions | 3.613 m2 Mecace & 4.600 m2 Acemetal | 40 x 160 (6.400 m2) | 40 x 64 (2.560 m2) |