hydroelectric power.

Hydroelectric Power

The power of water

A renewable energy

Hydroelectric energy, also called hydroelectric power or hydroelectricity, is a form of energy that harnesses the power of water in motion—such as water flowing over a waterfall—to generate electricity.

There are several types of hydroelectric facilities; they are all powered up by the kinetic energy of flowing water as it moves downstream. In addition turbines and generators convert the energy into electricity, which is then fed into the electrical grid to be used in homes, businesses, and industries.

hydroelectric power.

Advantages of working with us

Our large hydro solutions experience encompasses a wide range of solutions to meet all your needs

Reliability

More than 25 years experience in the sector.

Manufacturing

News components: welding, machining and surface treatment.

Engineering

Detailing, manufacturing, design and reverse.

Repairing

Of turbine components, gates and valves.

hydroelectric power.

Your reliable partner

A renewable energy

We are your reliable partner for the supply or rehabilitation of equipment in hydroelectric power plants:

We provide the most reliable solutions accompanying our customers to achieve their technological challenges and ensuring the highest quality:

- 12.313 components manufactured or rehabilitated by ACEBRON GROUP

- 121 projects in which we have collaborated

- 53 hydroelectric power plants to which we have supplied components or equipment or on which we have carried out rehabilitations

- 6 countries to which we have supplied equipment or components

Components

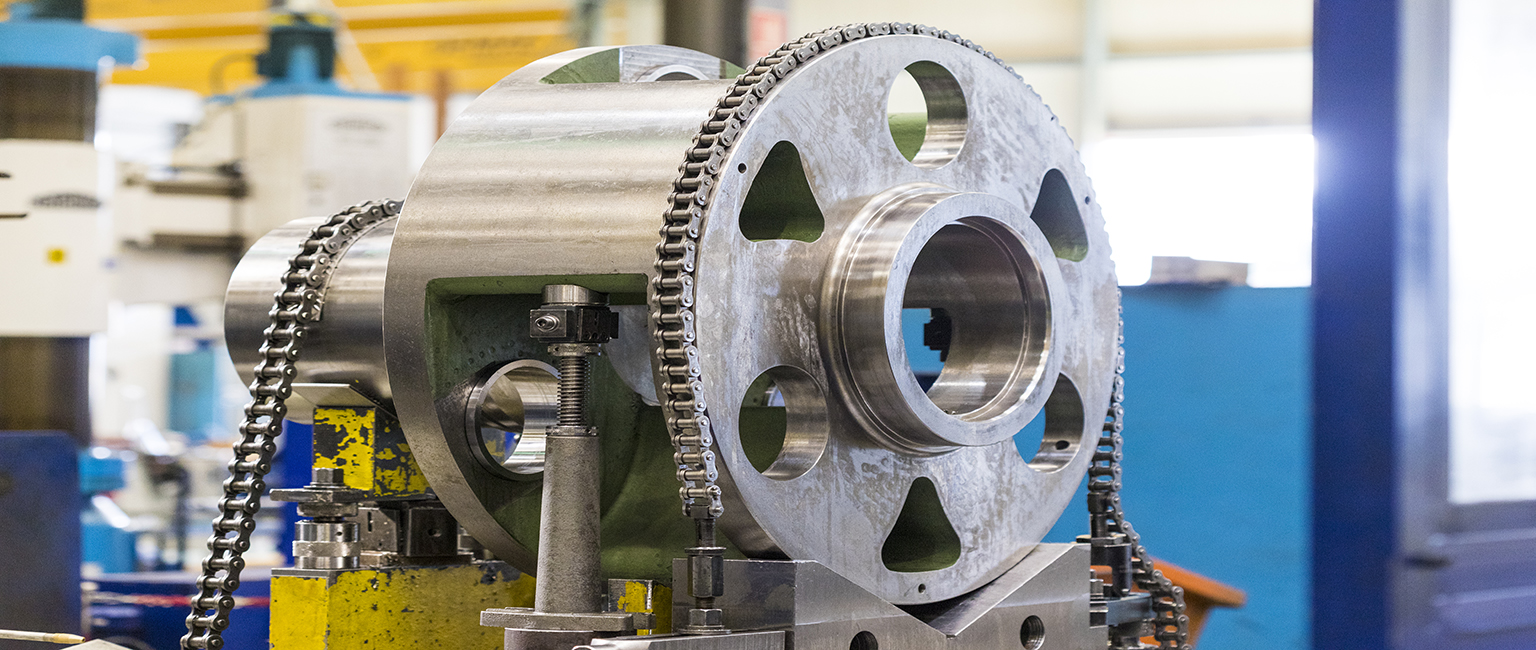

We use our own means and technical capacity to manufacture mechanical components, assemblies and sub-assemblies.

Reverse engineering:

Starting from a sample part, we can reverse engineer to manufacture and supply new components. This process is mainly carried out in our O & M section for old parts where there are no manufacturing drawings available and there is no availability in the market.

Although we specialise in the largest components, we have the capacity and means to manufacture practically all the mechanical components of Francis, Pelton and Kaplan turbines as well as other critical equipment for Hydroelectric Power Plants.

We are experts in manufacturing:

+ Caps+ Bearings+ Bushings+ Guiding vanes | + Rings+ Turbine casings+ Shafts+ Gratings |

+ Cones+ Crossarms+ Gates+ Labyrinths+ Chains and guides |

Projects

After 20 years working in the sector, we have managed to become the reference partner of the main technologists and utilities in the sector for their manufacturing and rehabilitation projects.

We have participated in important projects for the main Spanish hydroelectric power plants such as the CH de Jose María Oriol, CH de Aldeadavila, CH de Villarino, CH Torrejón, CH Ribarroja, CH Bolarque or CH Flix in which we have supplied or rehabilitated:

- Gates

- Crossheads

- Turbine components

- Valves

- Safety elements

Our scope of projects includes:

+ Engineering+ Dismantling and assembly in the workshop and in the plant+ Drawing up of plans | + Inspections, NDT, 3D measurements+ Surface treatment: Cleaning, sandblasting, painting+ Welding and metal sheet working |

Repair and Maintenance

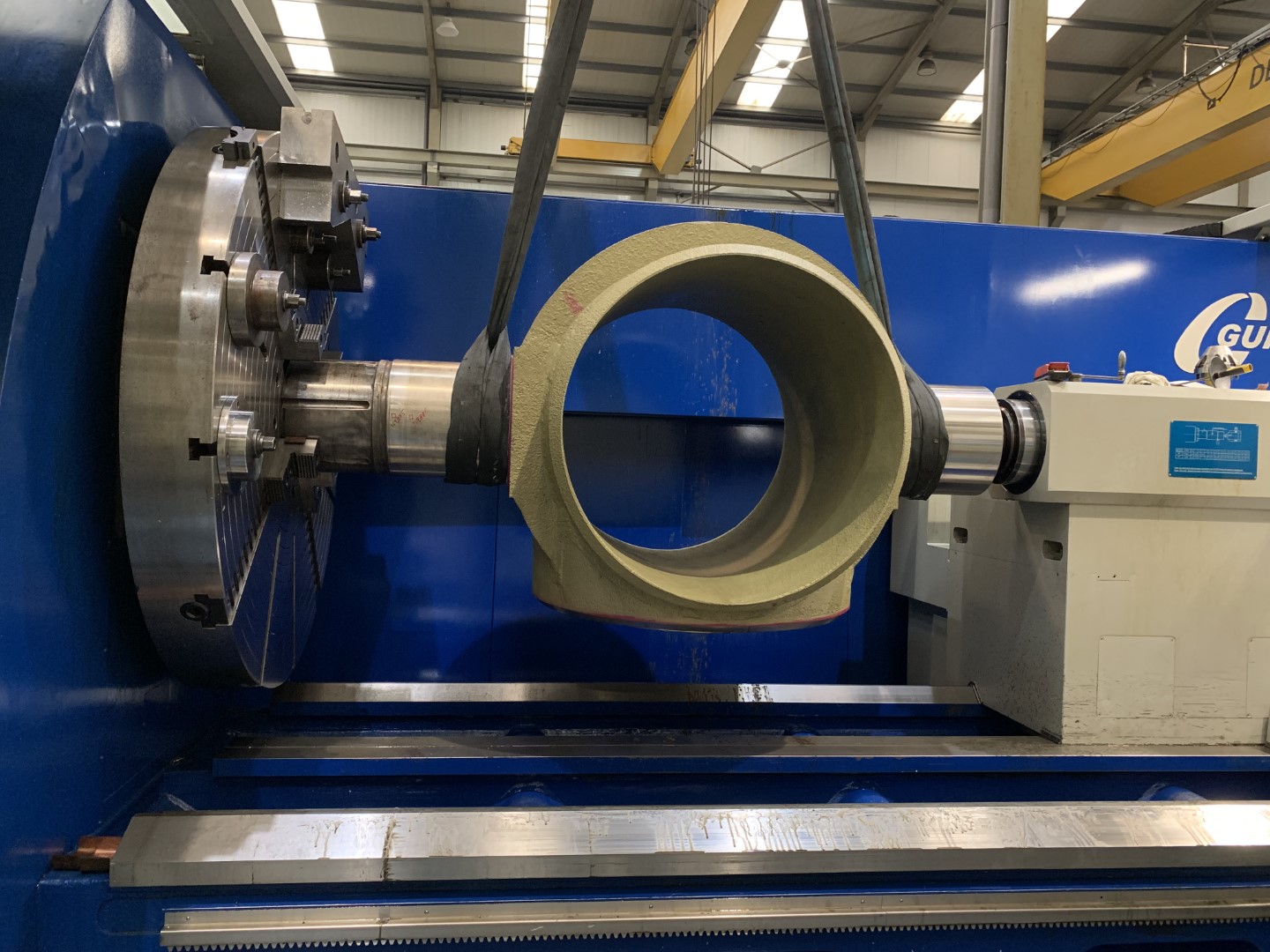

Our technical team and state of the art machinery enable us to undertake repairs and maintenance both on our own premises and in the customer’s facility.

Repair of hydroelectric power plants:

- Rehabilitation and repair of components of Francis, Kaplan and Pelton turbines (covers, bearings, bearing holders, guide vanes, distribution ring, regulation ring, fork and other servomotor parts, leakage tray, pump casing, shafts, labyrinths, tripod, carbon seal, distributor parts,…).

- Damper refurbishment

- Repair of valves

Scope:

- Disassembly and assembly in the workshop and at the head office.

- Drawing of plans.

- Inspections, NDT, 3D measurements.

- Cleaning, blasting, painting.

- Weld overlay, welding,

- Machining

- Supply of commercial elements.

- Supply of new parts that cannot be refurbished.

- Final testing.

- Reverse engineering.

Why choose us as a partner for your refurbishments?

- Flexible: we know how important it is to adapt to the continuous unforeseen events that arise in a rehabilitation and how important it is to meet the deadline.

- Proactive: we propose repair solutions in which we contribute our know-how and experience to provide the highest quality, seeking the best costs and deadlines.

- Reliable and transparent: we follow an open-door policy with our customers, who can monitor their projects in situ.

- Professional and seek the highest quality: we guarantee our work and repair components following the strictest manufacturing controls and quality tests.

We specialise in the following types of repairs and rehabilitations in which we are approved by leading technologists and utilities:

Quality Assurance

We have all the high-precision measuring tools necessary to guarantee the measurements of machined parts:

- Vantage laser tracker.

- Three-dimensional.

- Adjustment Bench.

- Balancing machine

In the surface treatment process we have highly qualified and certified FROSIO painters (Norsok 501) and a NACE International inspector (CIP Level 2) to guarantee the highest levels of quality and control.

Our manufacturing processes are certified according to EN1090-1:2009 /A1:2011 and UNE EN ISO 3834-2:2006 and we have a highly qualified engineering and product quality department:

- International Welding Engineer (IWE)

- Welded construction inspectors.

- NDT technicians

Industry 4.0

At ACEBRON GROUP we are committed to Industry 4.0 and to the complete digitalisation of the value chain.

Our 4 factories and all our machining equipment are connected to the production engineering department via industrial communications software.

We can send programs directly from the CAM department to all machines, improving productivity and increasing the reliability of the different processes. Through our virtual machines we are able to generate a simulation of the machining process, thus improving the efficiency, times and quality of our procedures.

We use these programmes and systems to machine complex and large components such as gearbox housings or bushings, ensuring precision and compliance with the necessary tolerances and geometries.

We also make use of Industry 4.0 tools to reverse engineer components through which we can proceed to the creation of new parts from used parts.

30 YEARS WITH THE BEST RESULTS.