CAPITAL GOODS.

Capital Goods

Providing global solutions

Technology and experience

We have the capacity and means to carry out the complete manufacture of capital goods and to carry out their subsequent O&M.

Services:

- Manufacturing: boilermaking and welding, machining, surface treatment, quality testing.

- O&M: Repair and maintenance

- Spare Parts

No matter the sector, we adapt to the most demanding requirements and specifications.

We have experience in supplying capital goods for sectors such as:

+ Food sector+ Petrochemical+ Mining+ Energy |

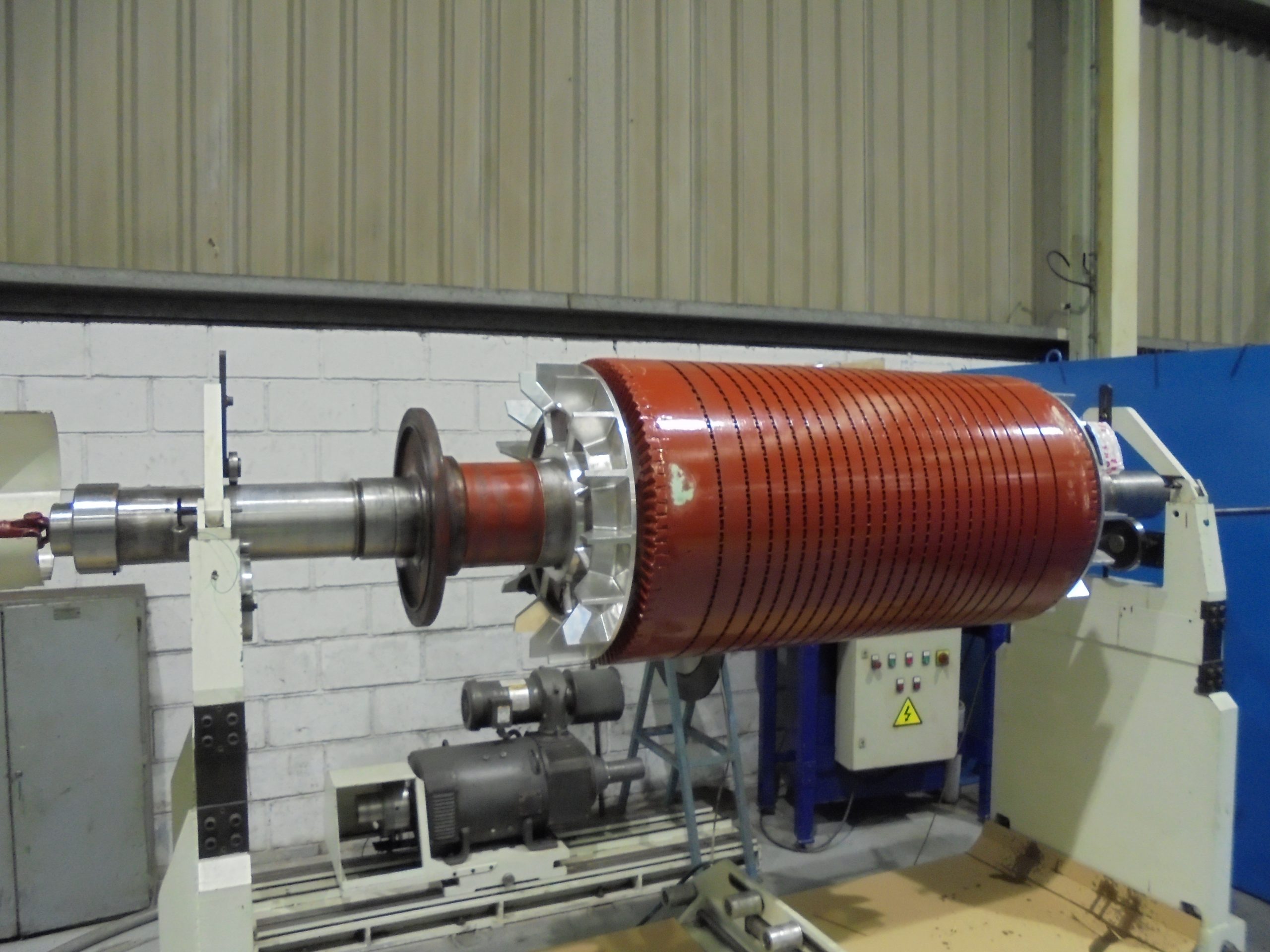

Components

We have more than 20 years of experience in manufacturing and supplying power plant components.

We manufacture with the highest quality, complying with all the regulations and standards required in each of the sectors in which we operate.

In addition, if it is a very old component for which we do not have manufacturing plans, starting from the sample, we analyse the material and carry out reverse engineering in order to manufacture a new component.

Tenemos la tecnología y el know how para poder fabricar prácticamente todos los componentes mecánicos y Spare Parts que una planta energética necesita, tales como:

+ Shafts+ Bearings+ Bearing carriers+ Covers | + Rollers+ Rings+ Discs+ Bushings+ Blades |

Projects

Highly qualified team and necessary technical means.

We are a serious and reliable supplier that can be counted on for the most responsible projects where precision, quality and commitment are required to ensure compliance with project specifications and requirements.

Acebron Group your equipment manufacturer

We have in-house capabilities to be able to carry out the complete manufacture and assembly of complex equipment with high quality requirements.

- Manufacture of slurrification unit skids CRI for the petrochemical sector.

Scope:

- Complete manufacturing

- Assembly

- Manufacturing tests

- Quality standard: Norsok M-101, Norsok M-120

Manufacture of 3 storage tanks

Scope:

- Complete manufacturing

- Assembly

- Manufacturing tests

- Quality standard: Norsok M-601

Repair and Maitenance

Highly qualified team and the necessary technical means.

We have a highly qualified team and the technical means to carry out repairs and maintenance, both at our plant and at the customer’s facilities, where we perform services such as:

- Refurbishment and reconditioning of equipment.

- Balancing

- Machining

- Special refurbishment

- Welding and boilermaking

- Surface treatments

In addition, if it is a very old component for which we do not have manufacturing plans, starting from the sample, we analyse the material and carry out reverse engineering in order to manufacture a new component.

Quality Assurance

We work to very high quality standards in terms of tolerances and precision. In order to meet these standards, we have temperature-controlled workshops and CNC machines during our manufacturing process.

We have all the high-precision measuring tools necessary to guarantee the measurements of machined parts:

- Vantage laser tracker.

- Three-dimensional.

- Adjustment Bench.

- Balancing machine

In the surface treatment process we have highly qualified and certified FROSIO painters (Norsok 501) and a NACE International inspector (CIP Level 2) to guarantee the highest levels of quality and control.

Our manufacturing processes are certified according to EN1090-1:2009 /A1:2011 and UNE EN ISO 3834-2:2006 and we have a highly qualified engineering and product quality department:

- International Welding Engineer (IWE)

- Welded construction inspectors.

- NDT technicians

Industry 4.0

At Acebron Group we are committed to Industry 4.0 and to the complete digitalisation of the value chain.

Our 4 factories and all our machining equipment are connected to the production engineering department via industrial communications software.

We can send programs directly from the CAM department to all machines, improving productivity and increasing the reliability of the different processes. Through our virtual machines we are able to generate a simulation of the machining process, thus improving the efficiency, times and quality of our procedures.

We use these programmes and systems to machine complex and large components such as gearbox housings or bushings, ensuring precision and compliance with the necessary tolerances and geometries.

We also make use of Industry 4.0 tools to reverse engineer components through which we can proceed to the creation of new parts from used parts.

30 YEARS WITH THE BEST RESULTS.