Excellence is our goal.

MECACE,MECACE, well-established player in the

largelarge machinedmachined componentscomponents

Highest quality product

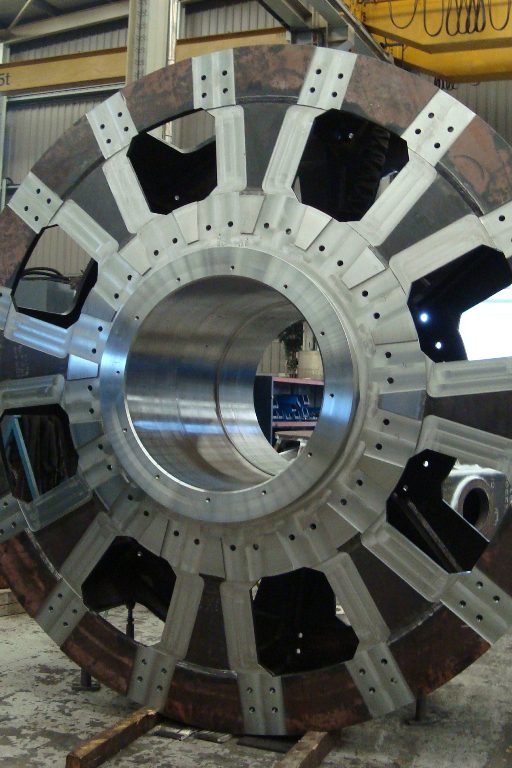

MECACE from its beginnings in the year 2000, has specialized in machining critical components for wind turbines (shafts, hubs, chassis, gearbox housings, etc.) with the goal of providing the highest quality product and excellence in customer service. Today we are a well-established player in the large machined components field with wide experience on both the national and international markets.

We provide tailor-made solutions in the technological machining of workpieces for most sectors in a wide range of materials and sizes both as serial parts (wind generation, railway and hydraulic sectors, etc.) and projects adapted to the specific needs of the customer (power generation, shipbuilding, machine tools, machinery, etc.). Our team collaborates with the customer on all projects to continuously improve product design and manufacturing processes.

excellence is our goal.

FullyFully finished productproduct

Focus on the TOTAL QUALITY of the service

MECACE integrates the capacities of the other companies in the ACEBRON GROUP to provide customers with a fully finished product including manufacture of entire mechanical assemblies and sub-assemblies (selection and procurement of top quality raw materials, process design, machining, coatings and metalwork), quality testing (three-dimensional and laser metrics, NDT, other types of test on request) and pre-assembly. Preventive and corrective industrial maintenance and repair and balancing of rotors, turbines and compressors complete our integrated technological service proposal.

We have state of the art machines such as line boring machines, conventional vertical and horizontal CNC lathes, machining centres, milling machines, balancers, etc. This intense investment in machinery enables us to meet the demands of any customer regardless of the sector or the size of the project.

The unbeatable geographic location of MECACE with its direct connection to the outer port, highways, airports and rail system ensures that customers benefit from fast, efficient logistics and reduced delivery times and transport costs.

SOLUTIONS BASED ON TECHNOLOGY.

ACEMETAL,ACEMETAL, solutionssolutions and technologytechnology for industrial machining

Total quality of the service

ACEMETAL was founded with the clear mission of satisfying customer needs by providing specific solutions and the best technology.

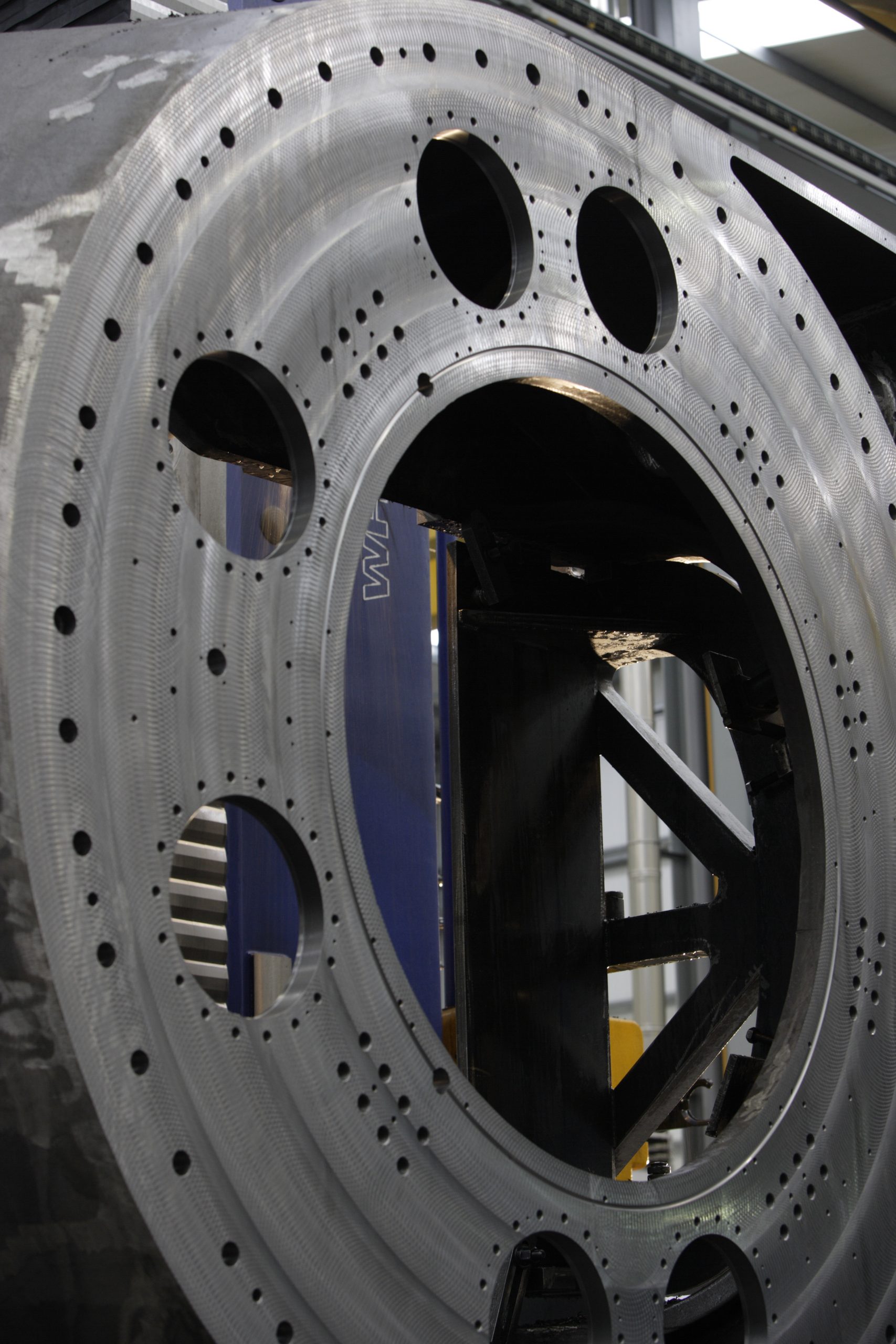

We specialise in the machining of medium and large components and the repair and refurbishment of components and equipment for the energy and industrial sectors.

Our wide range of services is unparalleled in the industry and includes:

- Machining and repair of gearbox casings and major wind turbine components (shafts, hubs, frames).

- Rehabilitation and repair of equipment and components for the hydroelectric sector.

- Re-engineering service that provides new solutions for our customers.

- Manufacture of new components for specific projects or series production.

SOLUTIONS BASED ON TECHNOLOGY.

ComprehensiveComprehensive quality controlcontrol

Department with the latest technology

We have state of the art machines such as boring machines, conventional vertical and horizontal CNC lathes, gantry milling machines, palletizing centres, balancers, etc. This intensive investment in machinery is complemented by comprehensive quality control in all the services we provide. We even have a specific MEASUREMENT and METROLOGY Department equipped with the latest technology including three-dimensional measuring devices, laser trackers and a settings workbench that ensures perfect calibration of the metrology equipment.

The unbeatable geographic location of ACEMETAL with excellent connection to the outer port, highways, airports and rail system ensures that customers benefit from fast, efficient logistics and reduced delivery times and transport costs.

providing a comprehensive service.

ACESAN,ACESAN, specialized in surfacesurface treatmenttreatment

Comprehensive service

ACESAN specializes in surface treatment (painting, shot blasting and metalization). These services are complemented by the machining capacity of the other companies in the ACEBRON GROUP to provide a comprehensive service to the customer.

This integration of the processes in the value chain in a single group of companies results in excellent service, enhancement of our own competitiveness, a high quality final product, reduction of transport costs and fulfilment of delivery deadlines.

The unbeatable geographic location of TALLERES ACESAN with excellent connection to the outer port, highways, airports and rail system ensures that customers benefit from fast, efficient logistics and reduced delivery times and transport costs.

WELDING THE GROUP TOGETHER.

ACECAL,ACECAL, firmfirm commitmentcommitment to the futurefuture growthgrowth of the Group

Quality and responsibility

ACECAL is the latest addition to ACEBRON GROUP, beginning its business activity in 2011. It is dedicated to boilermaking and the complete manufacture of welded mechanical components and represents a firm commitment to the future growth of the Group.