SURFACE TREATMENT.

Surface Treatment

We do the painting,

sandblasting and metallisation of new and refurbished parts

Making things last longer

Treatment of metal parts

Surface treatment is a manufacturing process that is carried out to give certain characteristics to the surface of an object. Metal parts are treated in order to protect them as well as their precision machining form rusting and corrosion. In some cases, the process may have the additional purpose of bringing the product to dimensional specifications.

Who are we working with?

We work for sectors with high quality requirements, such as nuclear, wind and hydro, in which we are approved by leading technologists and utilities.

In fact, we have a NACE International Certification (CIP Level 2) inspector for quality control of our products and highly qualified painters certified by ACQPA and FROSIO (Norsok 501).

Services

+ Paint applications+ Sandblasting | + Thermal Projection – Metallised+ Other surface treatments |

SURFACE TREATMENT.

Sandblasting

Different blasting systems

Removal of polluting materials

Sandblasting, shot blasting or abrasive blasting is the operation of propelling a fluid at high pressure, which can be water or air, or a centrifugal force with abrasive force, against a surface to smooth it or remove contaminating materials.

Blasting system

ACEBRON GROUP uses a blasting system with different abrasive materials such as: metal shot, corundum, glass sphere or copper slag with which we can achieve even the most demanding results such as Sa 3 according to the UNE-EN-ISO-8501-1 standard.

SURFACE TREATMENT.

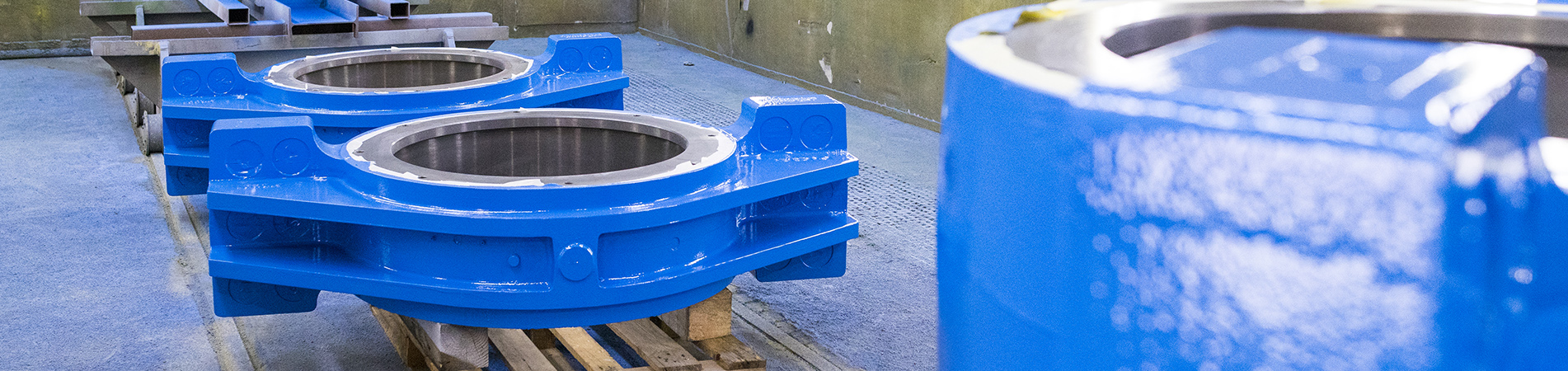

Paint applications

Uniform application

Range of painted

The painted range covers the industrial liquid mixture airless and aerographic processes that allow the spraying of paint at high pressure, allowing a quick and uniform application on all the treated parts.

Operation of machinery

The machinery used generates force with air and the difference with other methods is that it allows the atomization of paint without air since both components are not mixed at any point in the process. We have airless equipment with different pressure ratios, which allow the execution of complex painting cycles for C3, C4 and C5I corrosion environments according to UNE-EN-ISO 12944 with high durability.

SURFACE TREATMENT.

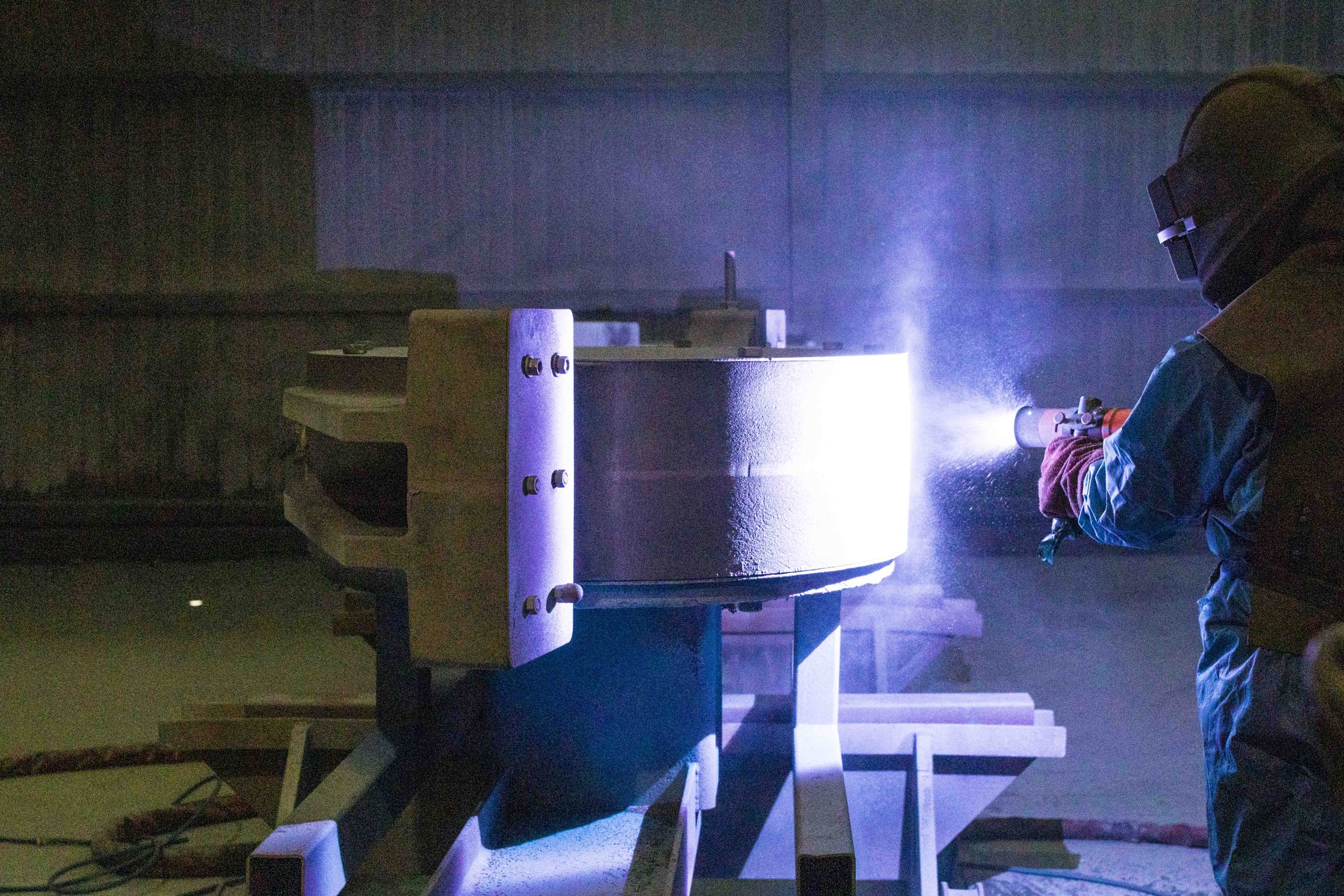

Thermal projections

Metallisation

Thermal spraying

Thermal spraying or thermo-spraying is a technique used in the manufacture of components that consists of projecting small molten, semi-molten, hot and even cold particles that are successively attached to a surface.

However, the metallization in particular, is that an oxy-fuel flame melts the filler metal (powder or thread) and by means of a propellant gas it projects the liquid particles on the substrate. This procedure is commonly used for corrosion and wear protection.

Objetive of the techique

The objective is to provide a surface treatment to the parts that are going to be subjected to extreme conditions of friction, wear, heat and / or mechanical stress.

Experience in the wind and aerospace sector

At ACEBRON GROUP we have extensive experience with applications of this technology for the wind power and aerospace sectors, metallising by electric arc fusion of one or more filler materials and/or alloys and projection of the mixture by means of pressurised air onto the part to be treated.

- 99% Zinc plating

- Metalizado con Zinc 85%+Aluminium 15% por proyección térmica

SURFACE TREATMENT.

Other procedures

Innovation

In addition, we have collaborators specialised in galvanising, chrome plating, dehydrogenation, heat treatments and other specific treatments on which we rely to provide a comprehensive service to our customers.

We carry out other types of surface treatments such as:

Services

+ Polyurethanes+ Epoxy resins+ Inorganic zinc silicates | + Caloric silicones+ Fluoropolymer coatings+ Belzonas application |

Maximum and minimum capacities of our machines

Surface Treatment Cabins | ||

Sandlasting (mm.) | Painting (mm.) | Metal spraying (mm.) |

| 12.100 x 4.980 x 5.120 mm | 12.000 x 3.790 x 4.280 mm | 10.450 x 5.740 x 5.380 mm |