INDUSTRIAL PLANTS.

Industrial Plants Solutions

We provide global solutions

Technology and experience

Since our beginnings we have been a global solutions company for power plants and we have specialised in providing services of:

- O & M: Repair and maintenance

- Manufacture of components and equipment

- Repair and rehabilitation of equipment

- Spare Parts

We operate in:

+ Combined cycle power plants+ Thermal power stations+ Nuclear power plants+ Biomass plants+ Hydroelectric plants |

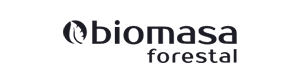

We have the technology and know-how to be able to manufacture practically all the mechanical components and Spare Parts that a power plant needs, such as:

+ Shaft+ Bearings+ Bearing carriers+ Covers+ Rollers | + Rings+ Discs+ Bushings+ Blades |

INDUSTRIAL PLANTS.

Manufacturing solutions

20 years manufacturing and supplying components for power plants

We manufacture with the highest quality, complying with all the regulations and standards required in each of the sectors in which we operate.

In addition, if it is a very old component for which we do not have manufacturing plans, we analyse the material from the sample and carry out reverse engineering in order to manufacture a new component.

Successful Cases

ACEBRON GROUP is your trusted equipment manufacturer.

We are a serious and reliable supplier that can be counted on for the most responsible projects where precision, quality and commitment are required to ensure compliance with project specifications and requirements.

We have in-house capabilities to be able to carry out the complete manufacture and assembly of complex equipment with high quality requirements.

- Industrial gearboxes

- Pumps

- Valves

- Drums

Water filtration equipment for the nuclear sector.

We have been approved to be a certified supplier for the complete manufacture of water filtration equipment for the nuclear sector.

This equipment complies with French market standards in the nuclear sector and is followed directly by the end customer to guarantee the highest quality.

We collaborate with our customers in the design phase to optimise costs and lead times.

Scope:

- Complete manufacturing: material supply, metal sheet working and welding, machining, surface treatment, heat treatment

- Blank assembly and manufacturing tests

- Three-dimensional measurement and NDT

Repair and Maitenance

Highly qualified team and the necessary technical means.

We have been awarded framework contracts for more than 20 years for maintenance in thermal power plants, for supplies of:

- Urgent machining

- Painting work

We carry out repairs and maintenance, both at our plant and at the customer’s facilities, where we perform services such as:

- Refurbishment and reconditioning of equipment

- Balancing

- Machining

- Special repairs

- Welding and boilermaking

- Surface treatments

If it is a very old component for which no manufacturing drawings are available. In fact we analyse the material from the sample and carry out reverse engineering in order to manufacture a new component.

Work carried out:

- Reconditioning of bale press for biofactory

- Repair of shredder for recycling plant

- Overhaul of auger for biomass plant

- Repair of valve assembly

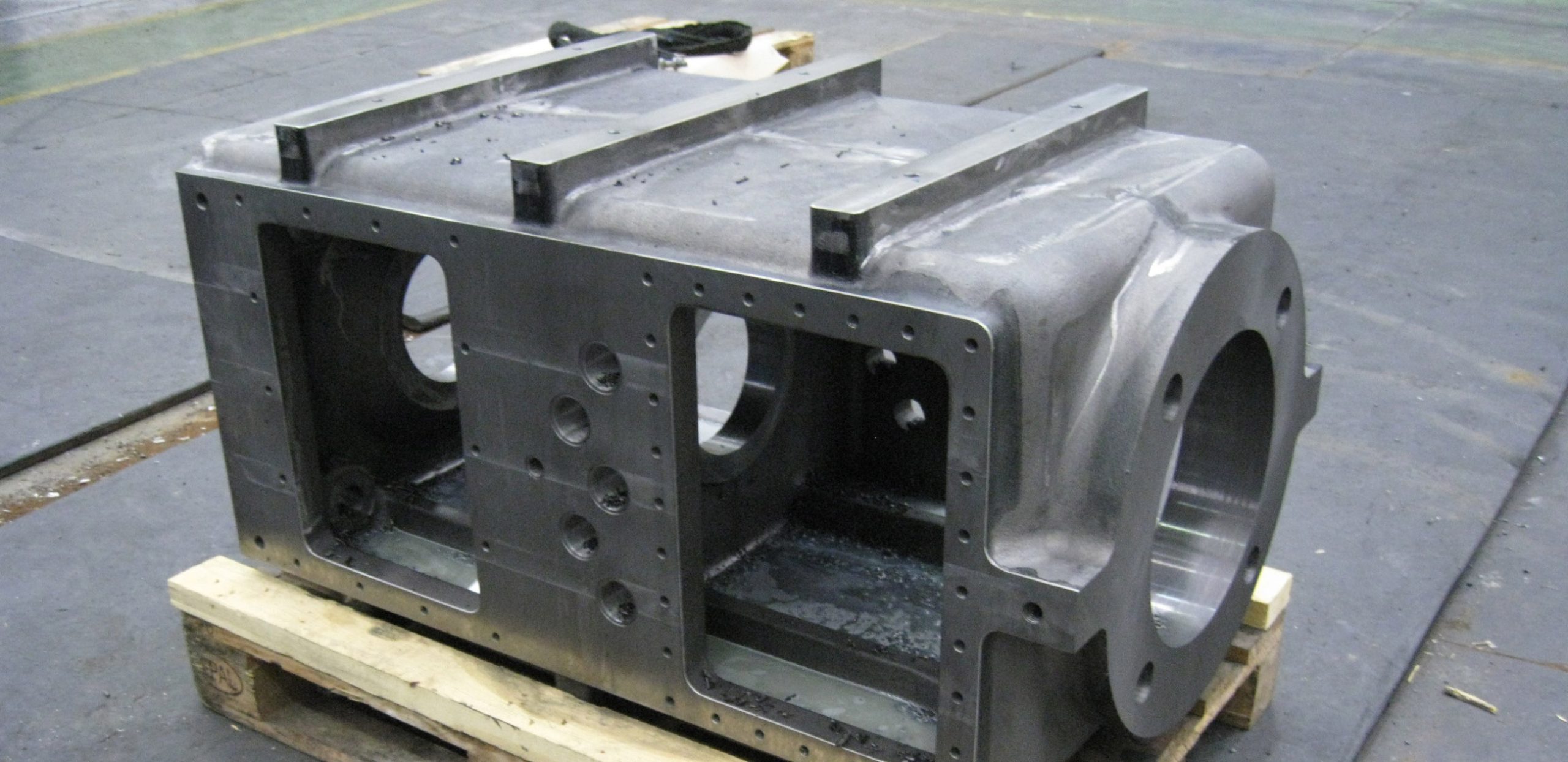

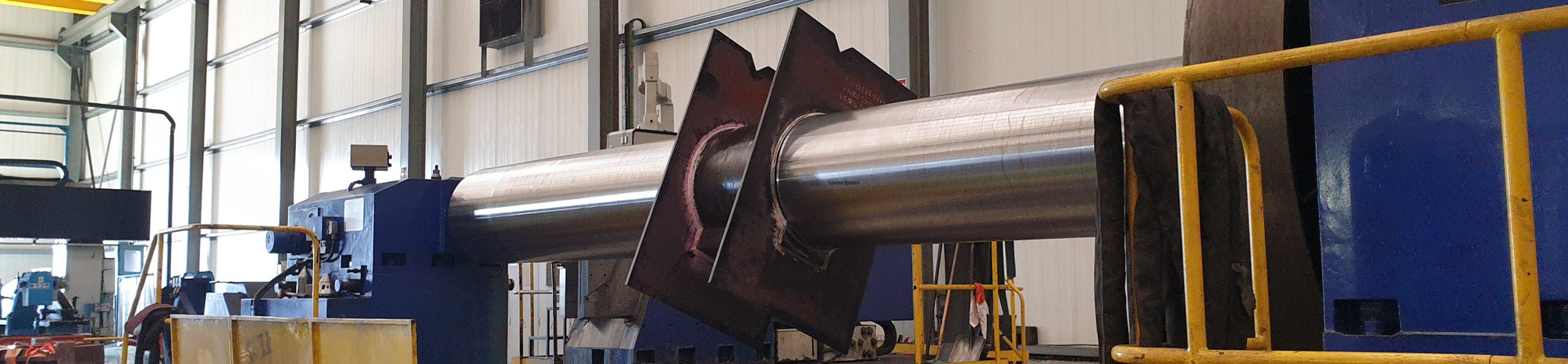

Turbine Repairs

We are a leading company with extensive experience in the repair of turbine rotors and compressors.

- Inspection

- Repair

- Machining

- Balancing

- Replacement of blades, seals and diaphragms

- Assembly and regulation

Quality Assurance

In order to meet these requirements, we have temperature-controlled workshops and CNC machines during our manufacturing process.

We have all the high-precision measuring tools necessary to guarantee the measurements of the machined parts:

- Vantage Laser Tracker

- Three-dimensional

- Adjustment Bench

- Balancing machine

In the surface treatment process we have highly qualified painters certified under the ACQPA standard, FROSIO (Norsok 501) and a NACE International inspector (CIP Level 2) to guarantee the highest levels of quality and control.

Our manufacturing processes are certified according to EN1090-1:2009 /A1:2011 and UNE EN ISO 3834-2:2006 and we have a highly qualified engineering and product quality department:

- International Welding Engineer (IWE)

- Welded construction inspectors

- NDT technicians

Industry 4.0

At ACEBRON GROUP we are committed to Industry 4.0 and to the complete digitalisation of the value chain.

Our 4 factories and all our machining equipment are connected to the production engineering department via industrial communications software.

In first place, we can send programs directly from the CAM department to all machines, improving productivity and increasing the reliability of the different processes. On the other hand through our virtual machines we are able to generate a simulation of the machining process, thus improving the efficiency, times and quality of our procedures.

Regarding these programmes and systems, we use it to machine complex and large components such as gearbox housings or bushings, ensuring precision and compliance with the necessary tolerances and geometries.

We also make use of Industry 4.0 tools to reverse engineer components through which we can proceed to the creation of new parts from used parts.

30 YEARS WITH THE BEST RESULTS.