Acebron Group | Capabilities and projects in the wind energy sector

Acebron Group has been the leading provider for key players in the wind energy sector for over 20 years, offering the most innovative, clean, and cost-effective solutions to drive your business.

At Acebron Group, we have the technical resources and necessary know-how to ensure quality and compliance with project requirements, as well as timely delivery. We always prioritize maximum safety throughout all manufacturing processes.

1. Repairs and Maintenance

We repair and rehabilitate components in a way that allows us to reuse up to 70% of the materials compared to a new item.

With our specialization in component repairs, we reduce CO2 emissions, contributing to a more sustainable and renewable world.

2. Components

OFFSHORE WIND

We have participated in multiple offshore wind projects, manufacturing the following components: mechanically welded components:

Foundations for Jackets:

- Primary Structure: Transition Pieces

- Secondary Structure: Boatlanding and Rest Platform

Foundations for floating structures: stiffeners:

- Transport tools

ONSHORE WIND

In addition to our experience in manufacturing components for offshore wind projects, Acebron Group undertakes the manufacturing of virtually all mechanical components of wind turbines, such as: main shafts, front and rear frames, hubs, bearings, etc..

3. Quality Control

In our company, we understand the high quality requirements of the industry and operate under high-quality standards.

Our quality system and manufacturing process are certified according to the EN 1090-1:2009 + A1:2011 EXC3 standard and the EN ISO 3834-2:2006 standard. Additionally, we have painters certified by FROSIO (Norsok 501).

4. Industry 4.0

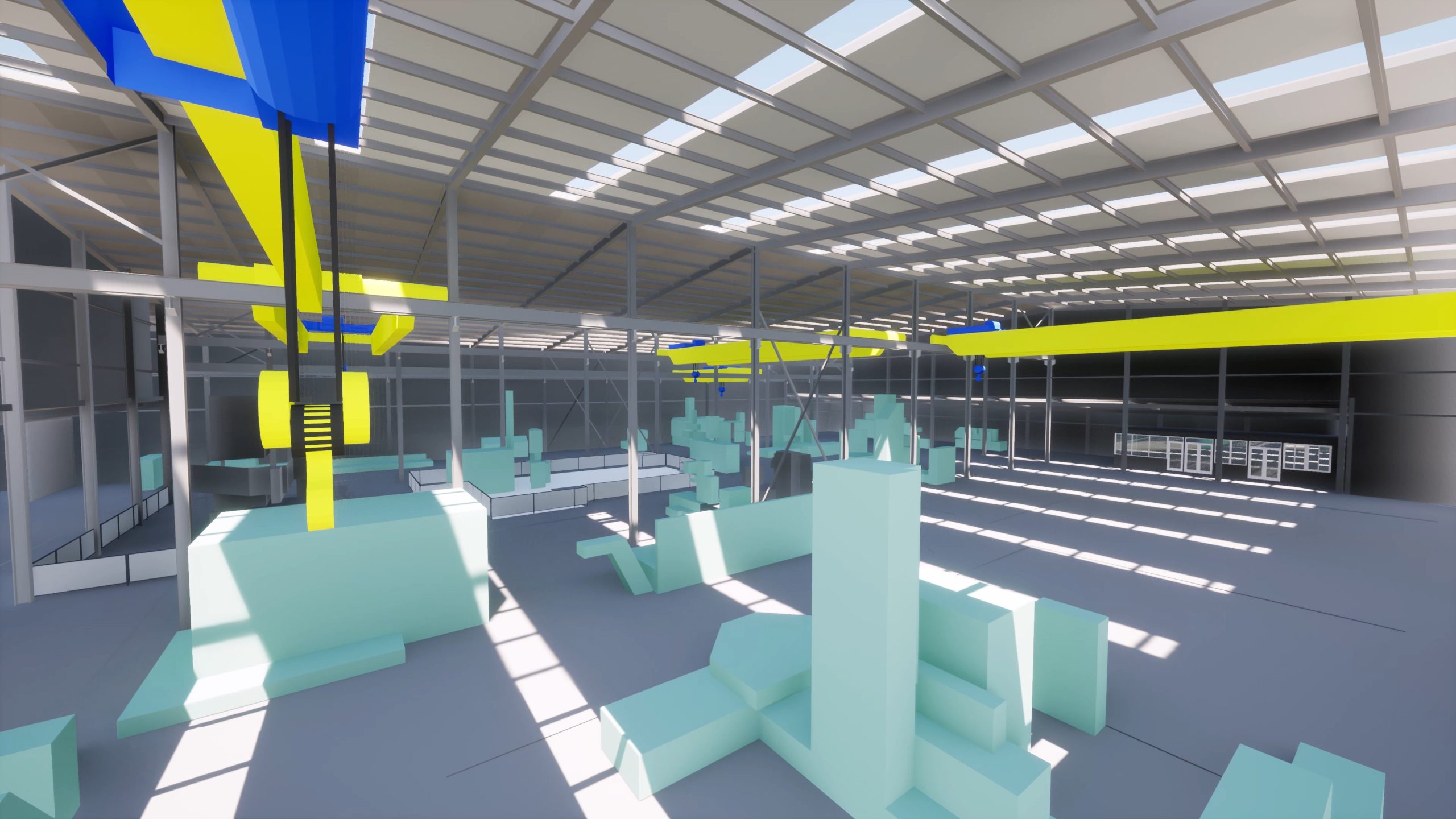

Digitalization of Facilities – Digital Twin and BIM Modeling

Through the use of a Digital Twin, we can create complete virtual tours of our facilities. This allows us to showcase our machinery, equipment, installations, and the technological and logistical capabilities of our company to clients. Additionally, it offers advantages such as:

- Reducing unnecessary travel

- Minimizing time and cost overruns

- Reducing carbon footprint

Using BIM (Building Information Modeling) digital workflows, we have modeled all the elements that make up our different facilities, generating a simplified model that enables us to work efficiently in our software and ERPs. This digital model also allows us to:

- Conduct advanced simulations of our processes to improve manufacturing efficiency

- Reduce time by optimizing logistical processes of components within our facilities

- Create real BIM simulations with our clients’ BIM components to streamline the bidding process, enhance documentation delivery, and have a precise study of the entire process.

Projects

The numbers speak for themselves, Acebron Group has been a leading company in the sector worldwide for over 20 years.

Currently, we are present in countries such as France, England, Scotland, where our work has allowed us to achieve significant milestones, including: