REPAIR AND MAINTENANCE.

Repair and Maintenance

Repairing is better than replacing

Circular economy

Repairing and refurbishing components for wind and hydro turbines significantly reduces CO2 emissions: sustainability at the core of Acebron Group.

What do we do at Acebron Group to reduce our carbon footprint? We repair and refurbish components so that we can reuse up to 70% of the materials compared to a new item. According to industry studies, a refurbished wind component saves on average 45% of CO2 emissions compared to a new part.

We are proud to contribute to a more sustainable and renewable world by specialising in the repair of renewable energy components and by pursuing a Reduce, Reuse and Renew policy.

Reconditioned components are not only sustainable, but also meet the most demanding quality specifications by complying with technical and quality standards to operate as new components, in some cases performing retrofits that even improve their initial characteristics.

When a component breaks down, at Acebron Group we can repair it and make it as good or even better than a new one with a complete refurbishment and with a new warranty. It is a sustainable and competitive solution, which helps to save costs for our customers.

HELPING YOUR BUSINESS.

Circular economy

We give components a second life

In a repair, some parts can sometimes be reused, but others have to be rejected because they cannot be repaired due to damage to the part. This component is scrapped and if possible, the old component is reverse engineered and a new one is manufactured. This component that cannot be reused, such as a wind shaft, is recycled with an authorised manager and given a new life by re-melting the material to manufacture other components.

HELPING YOUR BUSINESS

Sectors of expertise

Repair

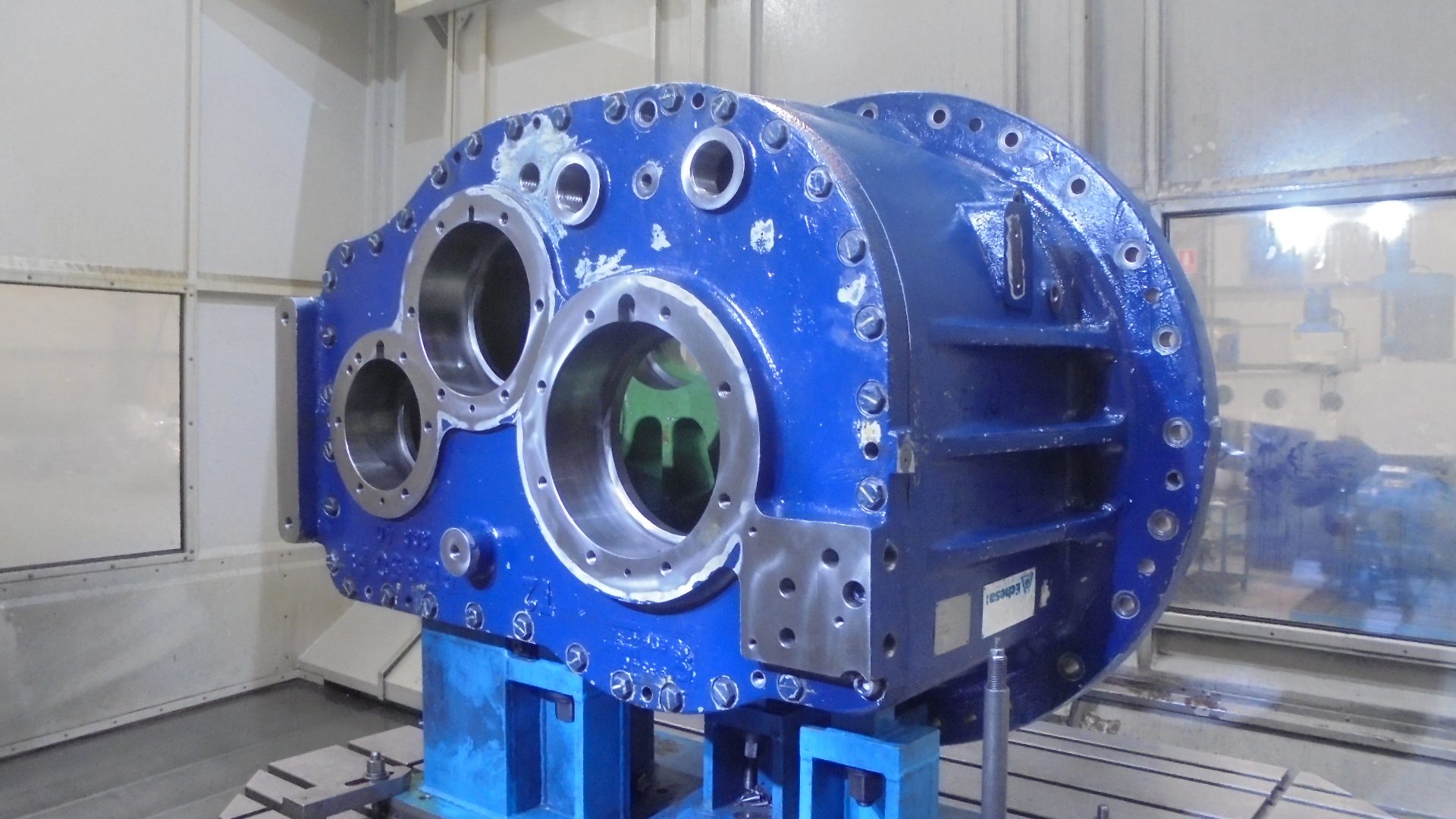

At Acebron Group we have more than 20 years of proven experience in repairs for the energy and industrial sector, especially in equipment for wind turbines and hydroelectric power plants. Our technical team and state-of-the-art machinery allow us to carry out repairs, refurbishments and maintenance both in our own facilities and in the customer’s facilities.

We specialise in the following types of repairs and rehabilitations in which we are approved by the main technologists and utilities:

Hydroelectric Power Station

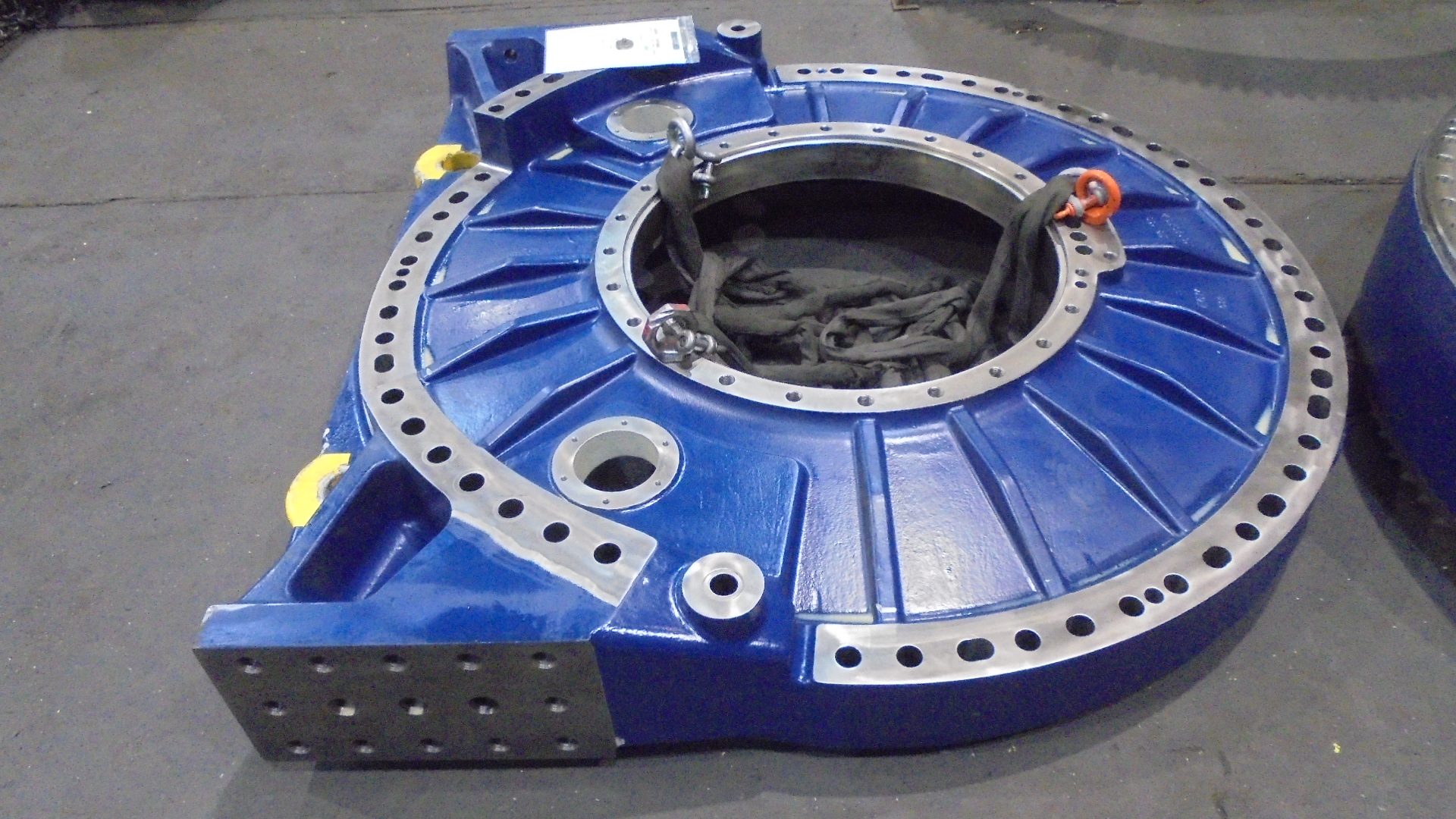

Our technical team and state of the art machinery enable us to undertake repairs and maintenance both on our own premises and in the customer’s facility.

Repair of hydroelectric power plants:

- Rehabilitation and repair of components of Francis, Kaplan and Pelton turbines (covers, bearings, bearing holders, guide vanes, distribution ring, regulation ring, fork and other servomotor parts, leakage tray, pump casing, shafts, labyrinths, tripod, carbon seal, distributor parts,…).

- Damper refurbishment

- Repair of valves

Scope:

- Disassembly and assembly in the workshop and at the head office.

- Drawing of plans.

- Inspections, NDT, 3D measurements.

- Cleaning, blasting, painting.

- Weld overlay, welding,

- Machining

- Supply of commercial elements.

- Supply of new parts that cannot be refurbished.

- Final testing.

- Reverse engineering.

Why choose us as a partner for your refurbishments?

- Flexible: we know how important it is to adapt to the continuous unforeseen events that arise in a rehabilitation and how important it is to meet the deadline.

- Proactive: we propose repair solutions in which we contribute our know-how and experience to provide the highest quality, seeking the best costs and deadlines.

- Reliable and transparent: we follow an open-door policy with our customers, who can monitor their projects in situ.

- Professional and seek the highest quality: we guarantee our work and repair components following the strictest manufacturing controls and quality tests.

We specialise in the following types of repairs and rehabilitations in which we are approved by leading technologists and utilities:

Wind Power

We are part of the sustainable supply chain of leading technologists and utilities. We apply our knowledge and experience of more than 20 years in the wind sector to be your reference supplier for repairs.

Repairs for the wind energy sector:

- Repair, rehabilitation and retrofit of gearboxes: At Acebron Group we specialise in the repair, rehabilitation and supply of the main gearbox components (gearbox casing, covers, planetary gears, crown gears, bearings, bushings, quick shaft, pitch system, oil divider…

- Repair and rehabilitation of the main components of the nacelle: main shafts, bushings, frames and extensions

- Complete rehabilitation of nacelles

Scope:

- Disassembly

- Cleaning, inspection, NDT and status report with repair proposal

- 3D dimensional control

- Reverse engineering

- Machining

- Special coatings: Chrome plating, dehydrogenation

- Surface treatment: sandblasting, metallising, painting

- Supply of damaged components and commercial elements

- Assembly and adjustment

- Verification, packaging and transport

- Quality report

Industrial Maintenance

Acebron Group has extensive experience in industrial repair and maintenance:

Our technical team is specialised and has a recognised experience carrying out repairs and maintenance for industries such as biomass, paper mills, petrochemicals, power plants, food for which we provide the solutions they need so that their plants do not stop and have the maximum performance:

+ Integral repair of gearboxes+ Valve repair+ Repair of industrial machinery+ Reverse engineering: using 3D technology, we can reverse engineer damaged components and manufacture new ones |

+ On-site repairs and preventive maintenance+ Special overhauls+ Repair and balancing of rotors: Inspection, repair, balancing, machining, replacement of blades, seals and diaphragms and assistance in assembly and regulation |