Experts in Machining Applied to Wind Power – Noticia

At Acebron Group we are experts in industrial machining for the manufacture of the parts that make up the wind turbines necessary for the production of WIND POWER onshore and offshore.

WHAT DOES INDUSTRIAL MACHINING CONSIST OF?

Industrial machining is the process of extremely precisely sized and shaped parts. It is a transformation for which the use of very specific machinery is essential and at Acebron Group we have more than 19 years experience in machining, surface treatment and boilermaking. We are experts in machining by chip removal, which consists of subtracting material in excess allowing us to manufacture high-precision parts.

The most common machining process goes back centuries and is by conventional chip removal, being an evolution of manual processes. They are, among others:

Turning: uses a lathe (single-edge cutting tool) to rotate the workpiece to remove excess and generate a cylindrical shape. The cutting movement is produced by rotating the workpiece and the feed movement by moving the lathe slowly parallel to the axis of rotation of the workpiece.

Milling: Uses a single or multi-edge cutter, lathe, or drill to cut the material into a straight surface. The main movement is perpendicular to the axis of rotation of the cutter and the feed movement is provided by the rotary cutter.

Drilling: This process is basically making circular holes into the material. The drill bit is mounted in the machine and, turning, penetrates and removes the chips from the material until the piece is formed.

Sawing: It can be manual or automated. Regardless of which way, the process is the same: The saw blade is slid back and forth and down cutting the material.

Wind Power, The Energy Of The Future

It’s a renewable energy, clean and that does not pollute. Wind energy is a type of kinetic energy produced by the effect of air currents. This energy can be converted into electricity through an electric generator.

In Spain, at the end of 2018, wind energy already covered 18.4% of the country’s electricity demand. In addition, since 2009 it is the third source of energy overtaking the coal power.

HOW DOES THE WIND POWER WORK?

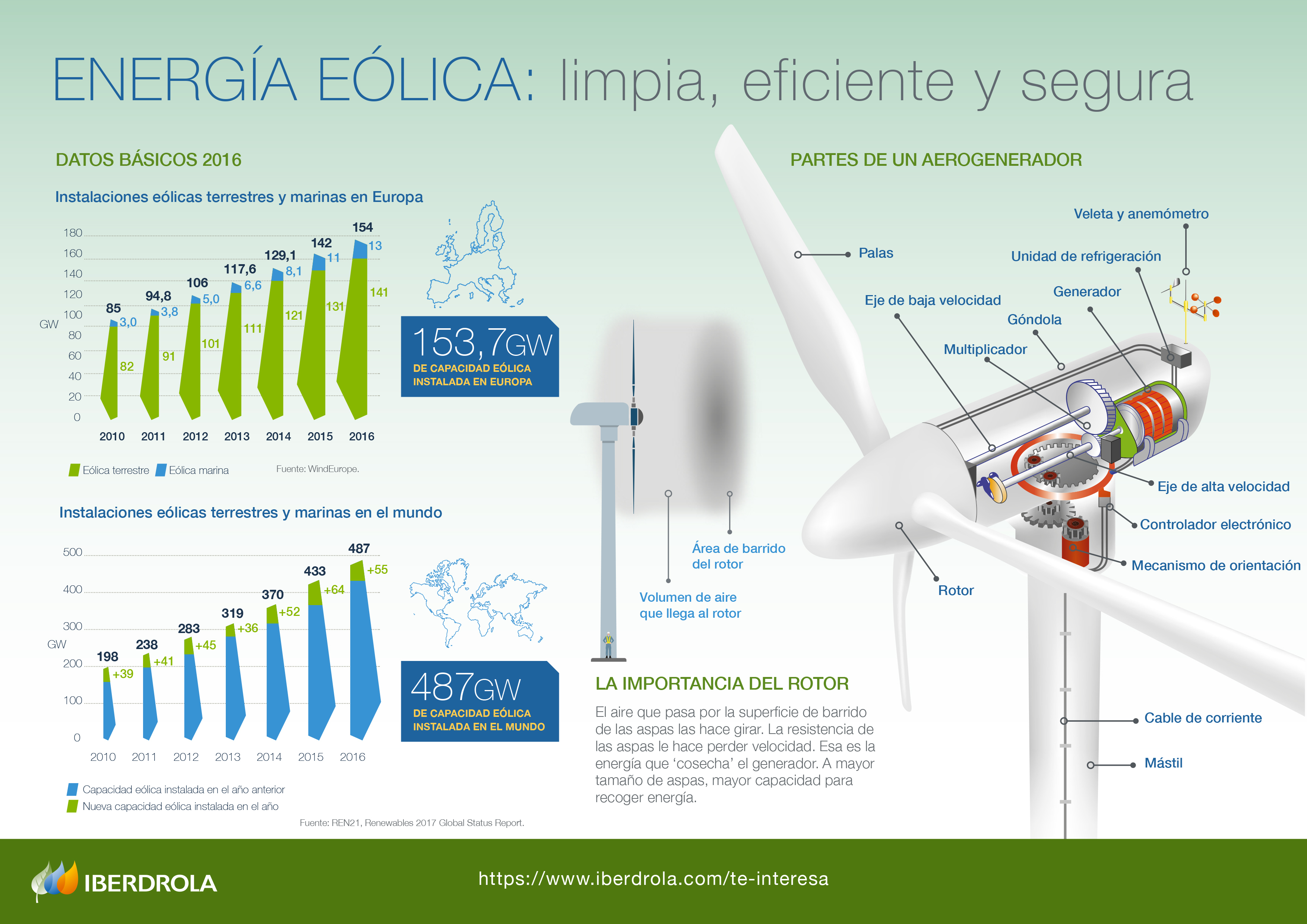

Wind energy is obtained from the kinetic energy of the wind that moves the blades of a wind turbine and converts it into electrical energy. These blades can move even in light winds. A gearbox raises that speed to more than 100 times and is transferred to the fast axis that moves at more than 1,500 revolutions per minute. This force is transmitted to the generator, where the kinetic energy is transformed into electrical energy. Finally, this energy has to be converted into high-voltage current to be suitable for consumption and to be brought to homes.

WHAT ADVANTAGES DOES IT PRESENT?

- It is a renewable and inexhaustible source of energy: you can always count on the original source that produces it.

- It doesn´t pollute: it does not produce toxic gases or solid waste. It is the cleanest source of energy after solar energy because it does not involve a combustion process.

- It is compatible with other activities: the placement of a wind farm does not interrupt other activities such as agriculture or livestock, therefore it has a positive impact on the economy.

- Low cost: both the cost of turbines and maintenance are relatively low and have a very long life cycle.

- It takes up little space: it needs less space than a photovoltaic energy field.

OFFSHORE WIND ENERGY

Marine wind power or offshore energy is the source of clean and renewable energy that is obtained by exploiting the power of the wind produced offshore, where it achieves greater and more recurrent agility thanks to the lack of barriers that hinder the air flow. When positioned offshore, the visual and acoustic impact is very low and offers the possibility of exploiting very large areas.

WIND ENERGY ONSHORE

Wind farms are usually located in rural areas, isolated from population centers to avoid to bother people with the noise and there are several factors to consider when installing it:

- The environmental impact.

- The energy potential of the area.

- The spatial, temporal and vertical variation of the wind over the years.

- The geological and geotechnical conditions of the site.

- The environmental, legal and territorial viability, as well as the accessibility to the place.

Acebron Group has more than 20 years experience in machining, surface treatment and boilermaking of practically all the components inside the nacelle as well as other components of the wind turbine, including the manufacture of tools and different components of off-shore wind turbines.

These are some of the machined and surface-treated components that we have supplied in short and medium series (50-500 units per year) to specialist in on-shore wind power:

- Main shafts (more than 4,600 units)

- Front and rear frames

- Bearings

- Brake discs

- Gearbox housings

- Generator housings

- Hubs

- Bed plates

- Extensions

- Blade spar caps

- Tower sections joint flanges

- Contraction rings

- Coupling plates

- Yaw drive crowns

- Gearbox mounts

We manufacture parts in series and by project for different types of wind turbines in the boilermaking and surface treatment section. These are some of the work carried out:

- Metallic components for the interior of towers

- Molds for blade beams (24, 32, 37, 42 and 53 Mtr.)

- Structures for transformers

- Generator housings

- Kits and assembly tools

- Transport and storage

We have been participating in off-shore power projects since 2016, having specialised in the manufacture of welded components for wind turbine supports, both for the primary and secondary structures. Our quality system and manufacturing process are certified with EN 1090-1: 2009 + A1: 2011 EXC3 and EN ISO 3834-2: 2006, and has FROSIO (Norsok 501) certified painters, meeting the highest manufacturing standards.

We are a leading company with extensive experience in the repair of different components of the wind turbine and gearbox, offering the following services:

- Repair and supply of gearbox components ( casings, back plate, planet carrier, oil divider, covers, slow shafts, trestles, bushings …)

- Complete repair including assembly and disassembly and supply of damaged components of slow shafts, frames or bushings.

- Reverse engineering from damaged components.