ACESAN workshops benefit from digitalisation

This solution will allow customers and partners to verify the group’s services and capabilities, reducing costs and streamlining processes.

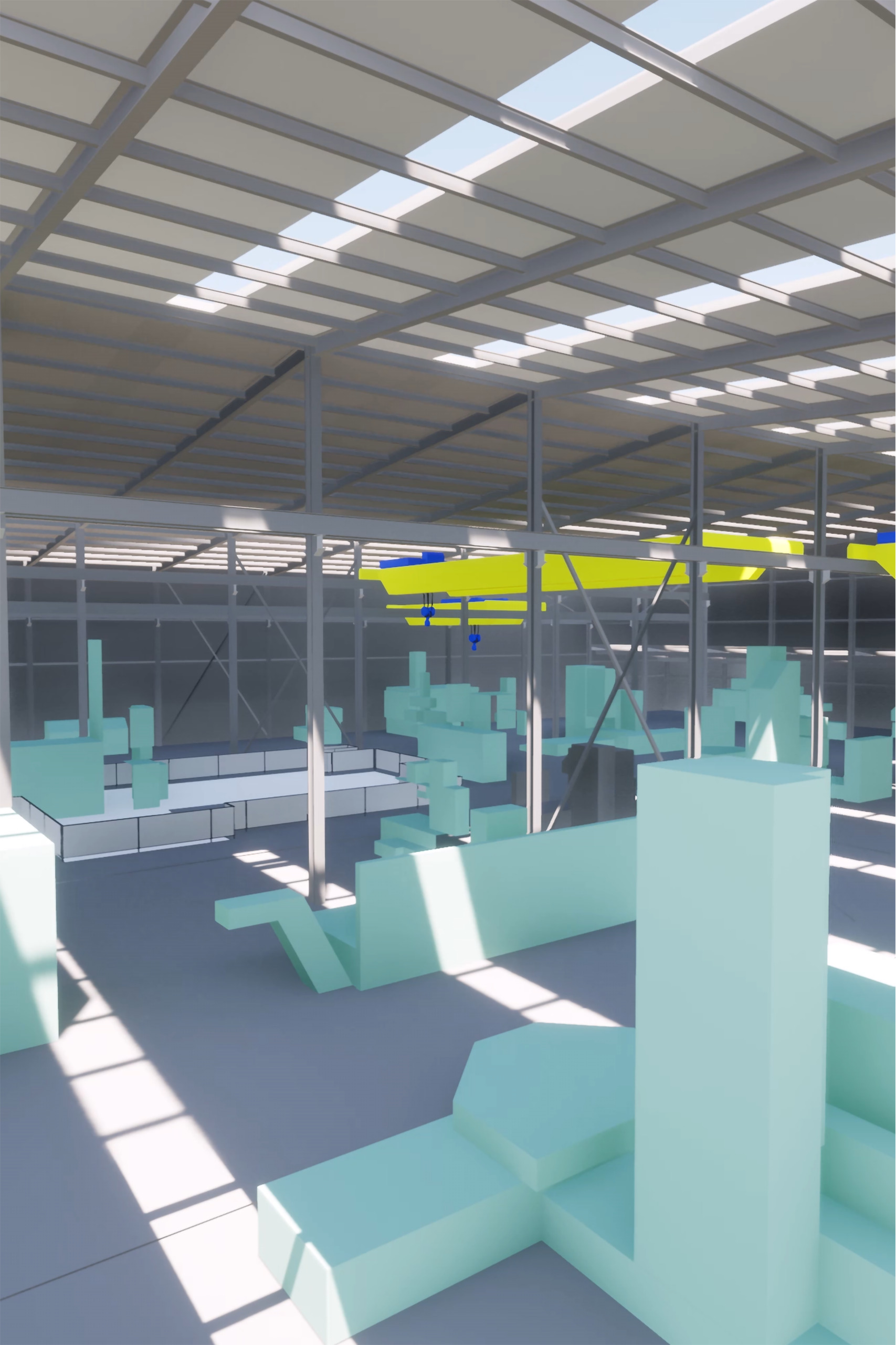

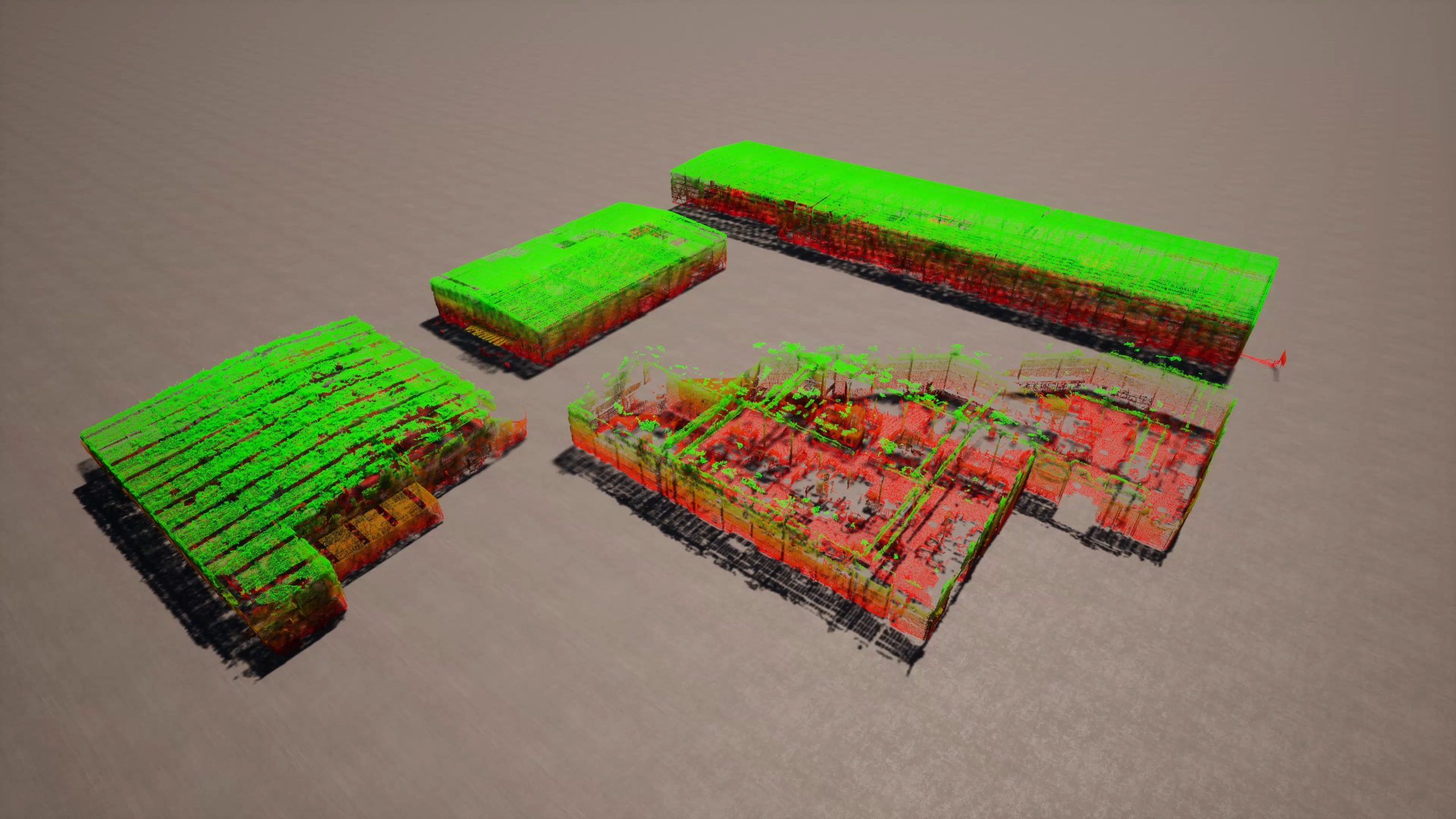

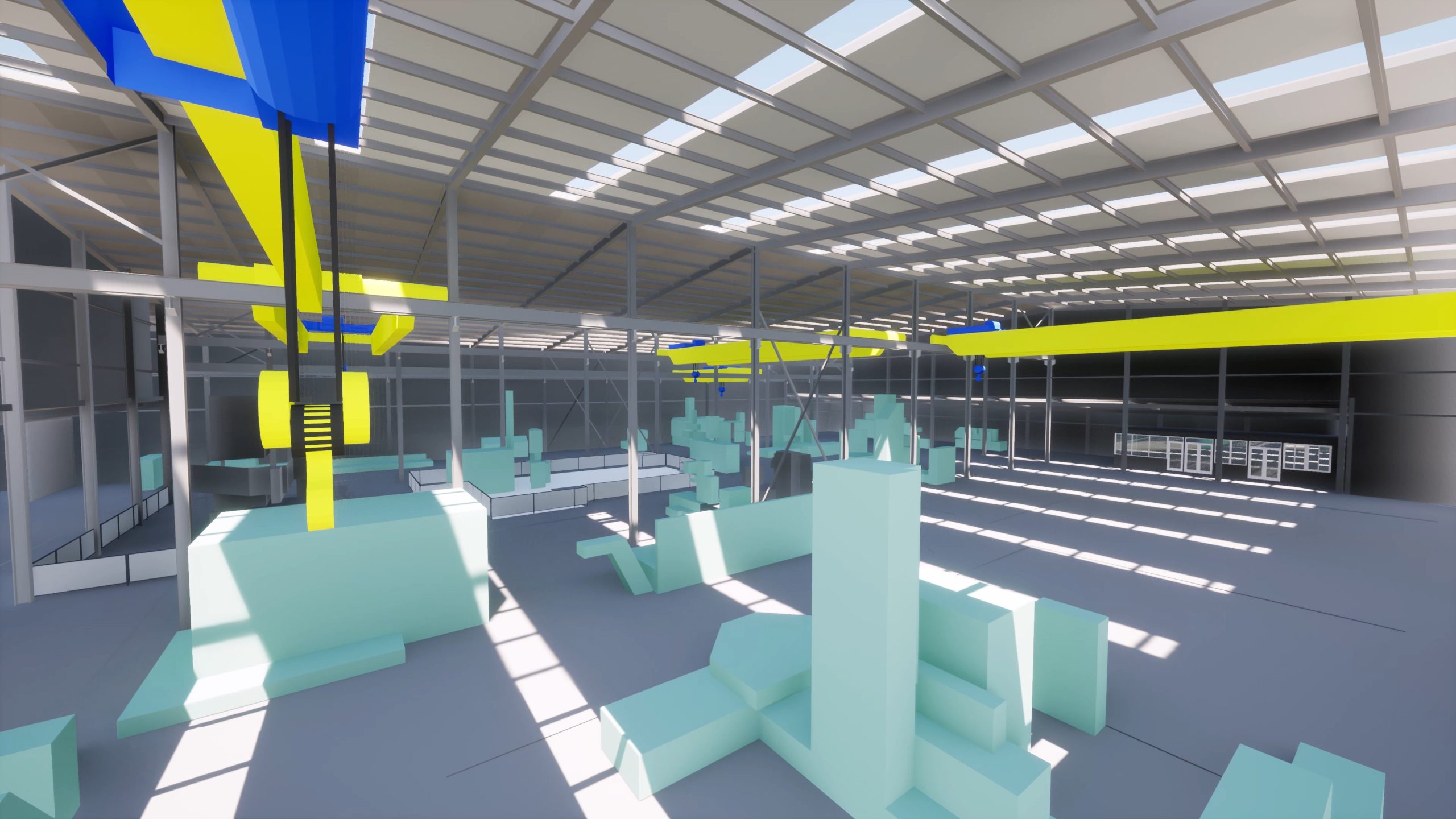

BIM Modelling and Digitalisation

Through the BIM digital flow, all the main elements that make up the building have been modelled, generating a simplified model that allows for agile work with the software and ERPs. Furthermore, by combining this technology with all the 4.0 process monitoring systems, the creation of the digital twin of all the Acebron Group’s warehouses has been achieved.

Competitive advantages

The implementation of the digital twin in ACESAN has improved the efficiency and quality of production processes, in addition to:

- Optimising processes: the creation of the digital twin has made it possible to simulate and optimise production processes, identifying and solving problems in advance.

- Improved efficiency: by having a digital representation of the processes, it is possible to identify and eliminate unnecessary activities and improve efficiency in the use of resources.

- Predicting results: the digital twin allows predicting the performance of production processes. This helps to make informed production decisions and improve quality.

- Reduce costs: by optimising processes and improving efficiency, costs associated with production are reduced, increasing profitability.

OBJECTIVES

In addition to the multiple competitive advantages, the following objectives have been achieved:

- To have a complete digital knowledge of the plant

- To generate a standardised digital BIM workflow.

- Generate new business opportunities through clients who demand this technology in their projects.

- Generate a digital value chain for customers

- Optimise costs by eliminating manual processes

- Generate simulations to optimise costs in logistical flows within the warehouse

- Generate an experience that allows customers to get to know the company virtually.

- Generate a workflow that provides internal value: knowledge of facilities and equipment, improvements in maintenance flows, occupational risk prevention, incident prevention, etc.

“By combining the Digital Twin with all the 4.0 monitoring systems of our processes, we are taking a leap towards creating a digital model of our company”. – Rebeca Acebrón (CEO Acebron Group).