Optimization of production thanks to Industry 4.0

In Acebron Group, we stand out as pioneers in the manufacturing and machining of industrial components, marking a milestone in the evolution of our processes with a significant and strategic advance in the digitalization of our facilities. The implementation of digital twins in the plants represents a milestone in the adoption of Industry 4.0, marking a new era in the optimization of production.

Digital Twins and BIM Modeling at Acebron Group

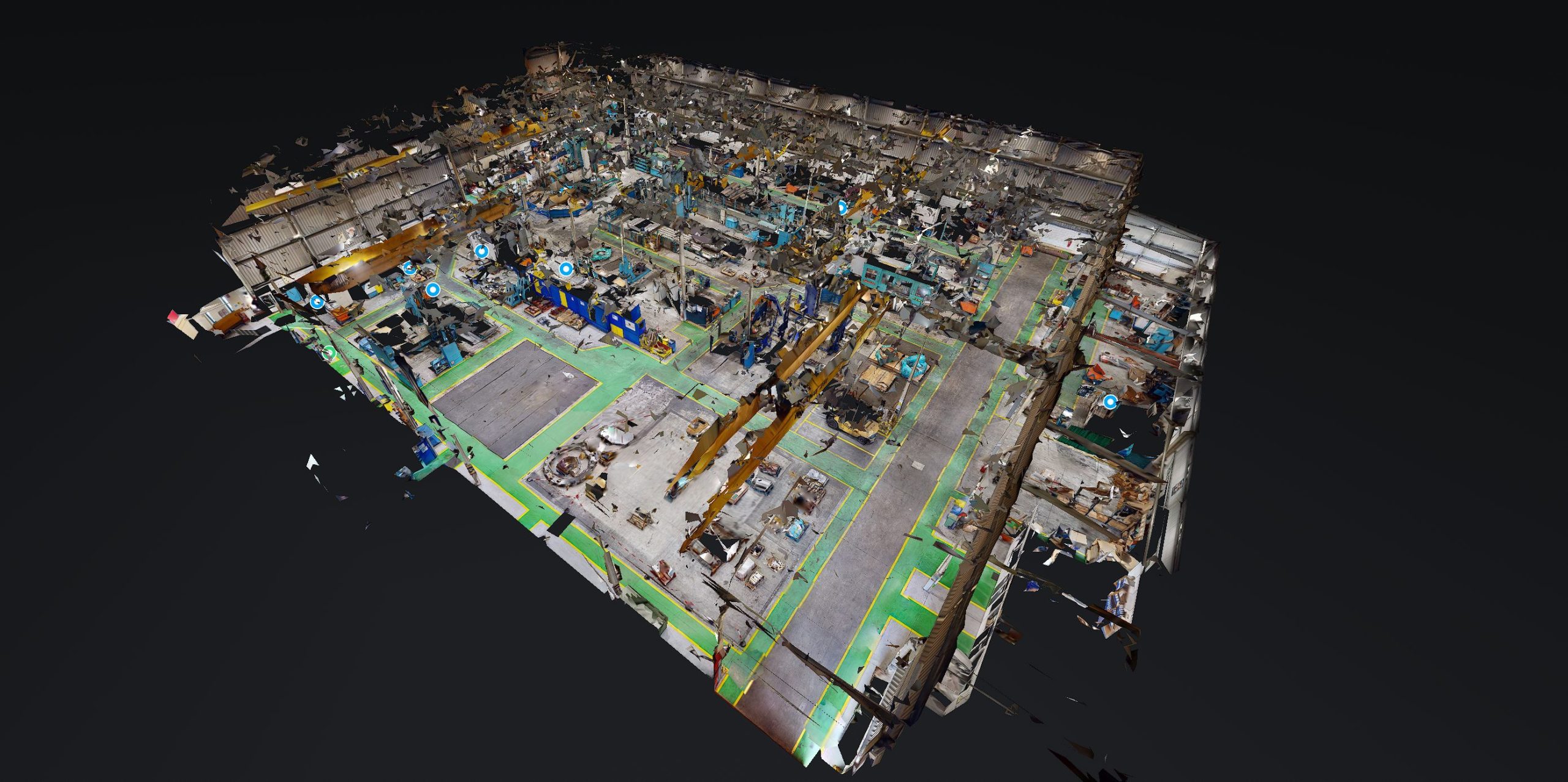

We have carried out the digitalization of our facilities using advanced laser scanner technology, creating a precise and detailed point cloud. This digital twin allows for complete virtual visits of the facilities, showing clients the machinery, equipment, and technological and logistical capabilities. This advance offers significant benefits such as the reduction of unnecessary travel, minimization of extra costs, and a decrease in the carbon footprint.

Acebron Group Participation

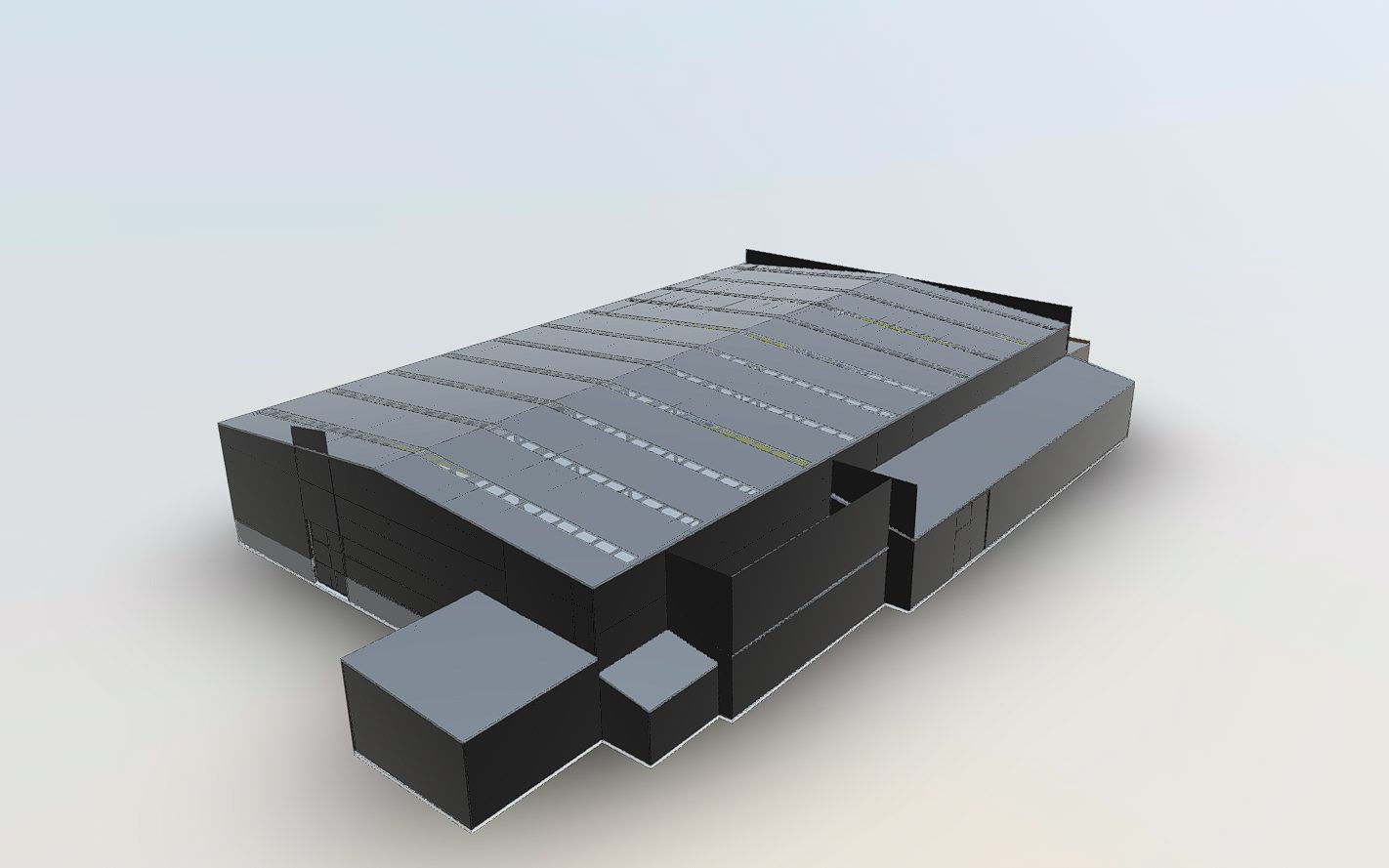

Through the BIM digital flow, we have modeled all the elements of our work centers, creating a simplified model integrated with its software and ERP. This digital model enables the generation of advanced simulations to improve manufacturing efficiency, optimize logistical processes, and streamline the bidding and documentation processes with precision and detail.

With the implementation of the BIM digital twin, we have managed to enable a block on our website, exclusive for clients, which allows viewing the photogrammetric models and performing a 360º virtual visit of the facilities. This tool strengthens customer trust and provides a complete view of the company’s services and capabilities.

The use of the digital twin offers us great advances in terms of performing compatibility simulations with the facilities and capabilities of the machines, optimizing workflows for the processing chain, and generating automated BIM documentation. These practical applications demonstrate Acebron Group’s commitment to innovation and continuous improvement.

Our Improvement Processes

Thanks to this implementation, we have experienced a significant transformation in our production processes. These technologies have not only allowed for a deeper visualization and understanding of the company’s operations, but they have also led to tangible and measurable improvements in several key aspects:

- Improved Efficiency in Production: The ability to simulate and optimize processes using the digital twin has led to a significant reduction in production times. By anticipating and solving problems before they occur in the physical environment, Acebron Group has achieved greater operational efficiency.

- Optimization of Resources: The implementation of these technologies has enabled us to manage resources more effectively. With precise simulations and detailed analysis, the company has optimized the use of materials and human resources, reducing costs and minimizing waste.

- Improvement in Product Quality: The accuracy provided by BIM modeling has improved the quality of the final product. By being able to visualize and virtually test components before physical production, errors have been reduced and quality standards improved.

- Increased Customer Satisfaction: The ability to offer virtual tours and improved transparency in production processes has strengthened the relationship with customers. This increased trust and understanding have led to greater customer satisfaction and opened new business opportunities.

- Reduction of Environmental Impact: The optimization of processes has contributed to a notable reduction in the company’s carbon footprint, aligning Acebron Group with sustainable practices and environmental responsibility.