Extending the life of metal components

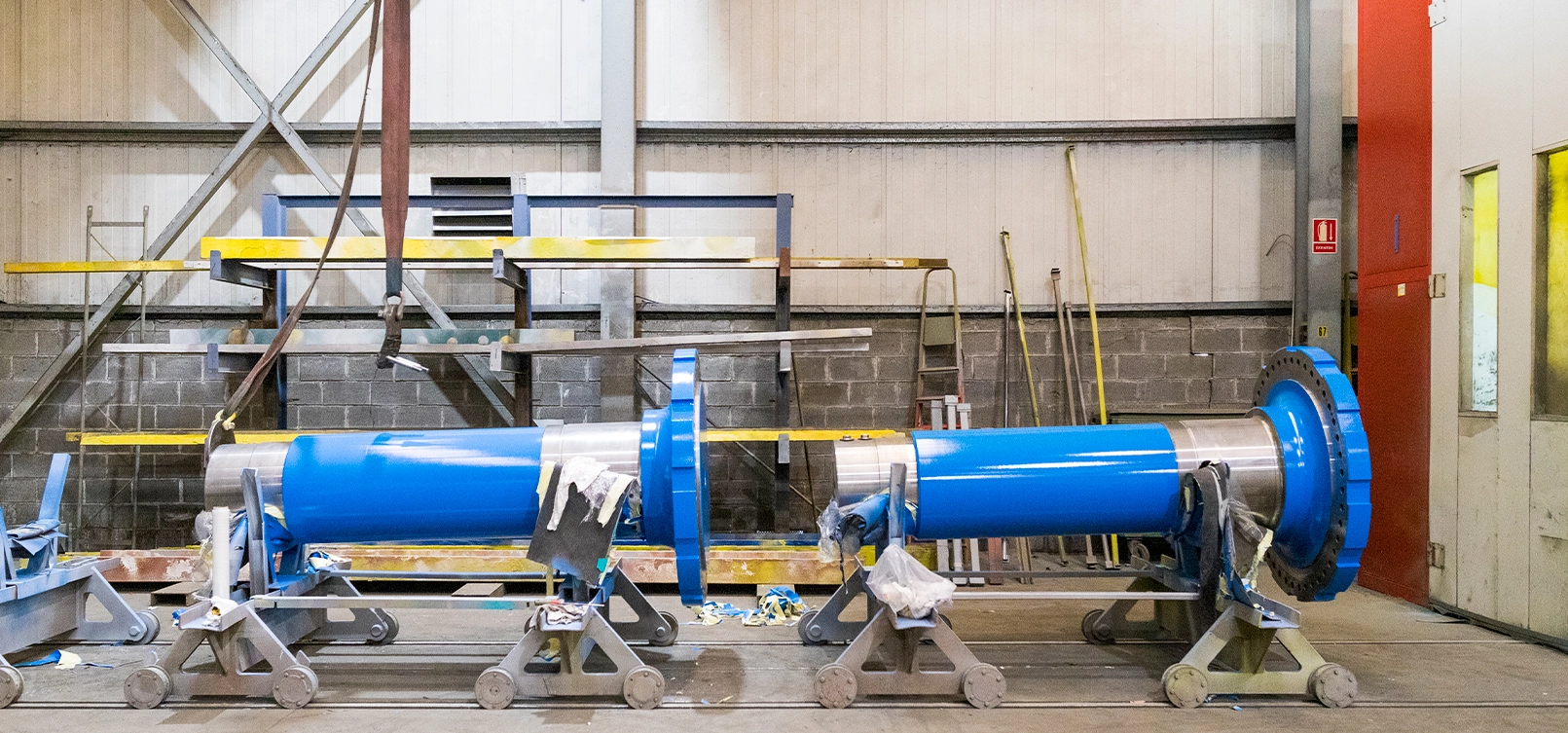

Specialised in sectors with high quality requirements such as nuclear, wind and hydraulic. We have a NACE International certified inspector (CIP Level 2) for the quality control of our products and highly qualified painters certified by ACQPA and FROSIO (Norsok 501.

Somos tu socio de confianza proporcionando soluciones a medida

Acebron Group es tu socio, nos preocupamos por tus necesidades y te proveemos con las soluciones más innovadoras, limpias y eficientes para impulsar tu negocio.

SURFACE TREATMENT.

Painting,Painting, blastingblasting and metallisingmetallising of industrial parts

More than 30 years of professional and business experience in surface treatment

We help your companycompany to achieve its objectivesobjectives

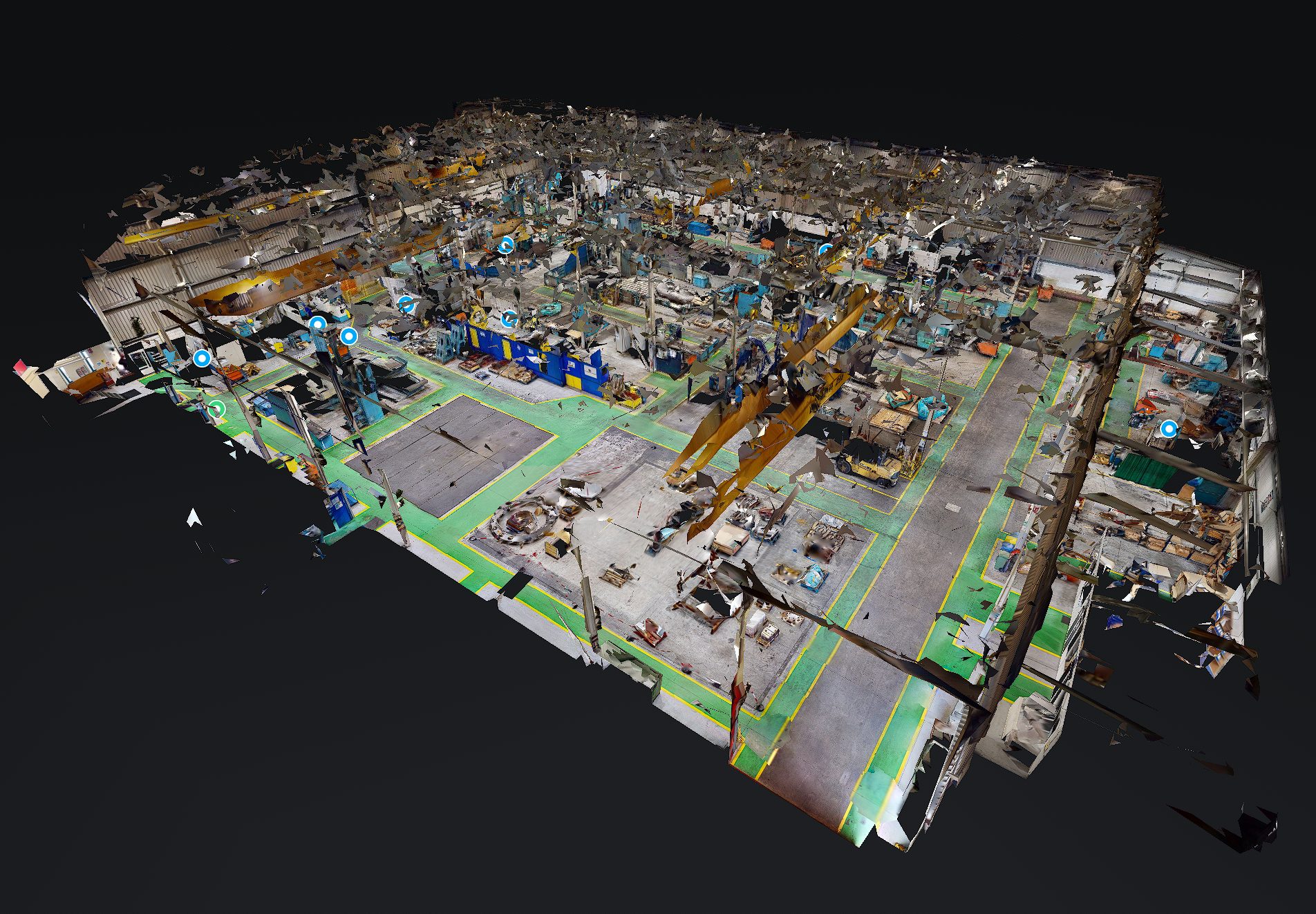

We have over 30 years of experience offering the best manufacturing solutions to help your business grow.

NewsNews Talleres AcesanAcesan

Excellence is our goal.

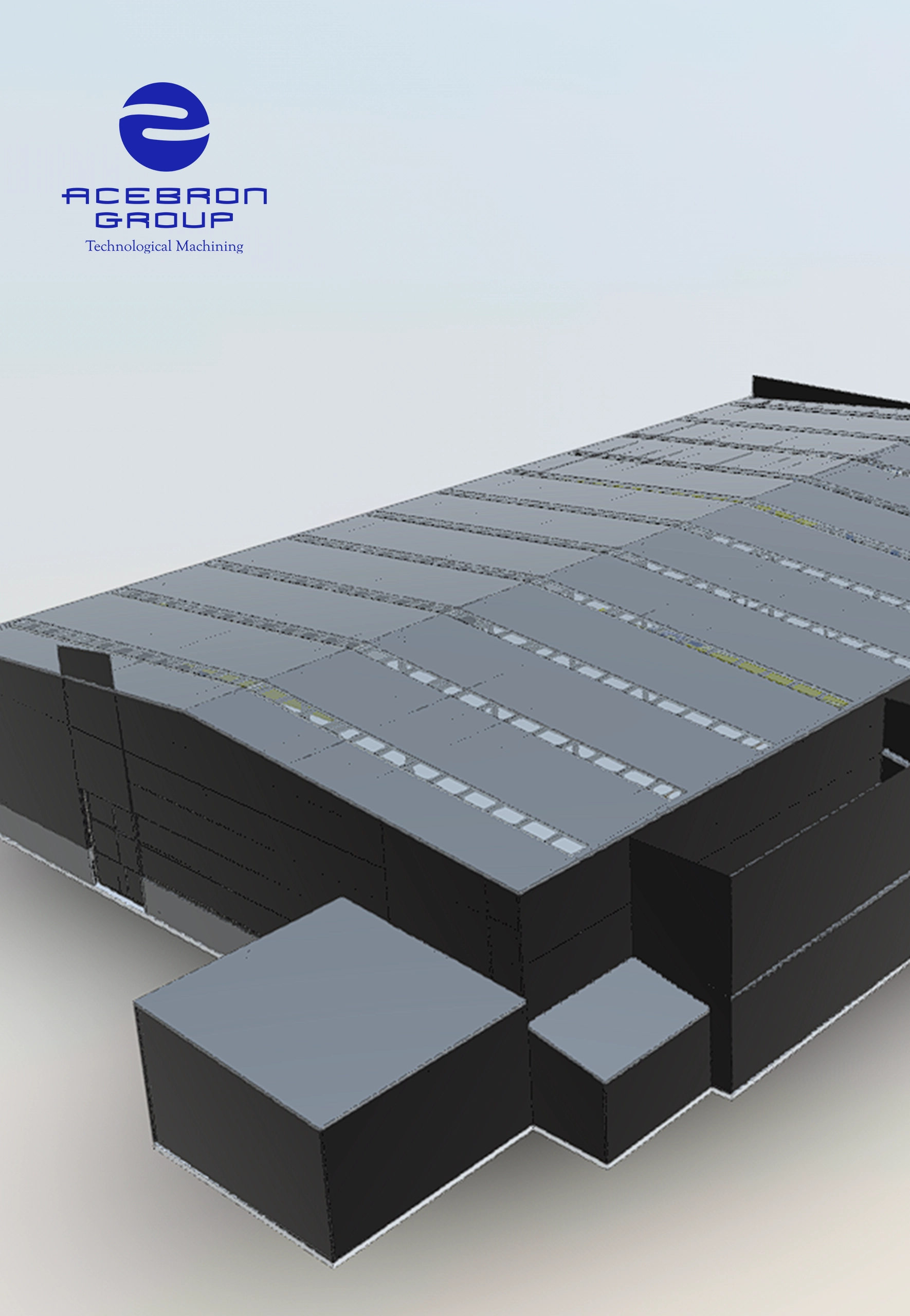

RequestRequest access to the virtual tourtour ofof ourour facilities

High quality product.

SHOP ONLINE ACESAN.